I finally installed my Beef Racks and the bow on both sides disappeared.

This makes it apparent that the upper honeycomb/extrusion assembly needs beefing up…pun intended. Maybe two of the beef bars extrusions should be made stock. Just up the price of the GFC a little bit perhaps something less than it costs to retrofit. It would be a good selling point that the GFC would include a racking system. I have three of the Beef crossbars but I suspect two would be sufficient.

To play devil’s advocate, I think one of the big things going for GFC is it’s lowest price point in the market. If the bow isn’t hurting anything and not everyone needs beef racks than why add an unnecessary cost? It’s just like a truck’s towing package, it generally creates a better truck but not everyone needs it so why have the extra cost.

It’s a design issue. The extrusions shouldn’t bow. I think that there’re some cases of the bowing causing the upper extrusion to not align with the lower so that the top wouldn’t close without pushing to one side. Also, over time the bowing might cause a failure of the glue that attaches the roof to the extrusion thereby causing a leak and hurting structural integrity.

There might be a less expensive way of assuring structural integrity other than the beef racks.

It is not a design issue—GFC engineered it so that the honeycomb material can flex while off-roading and driving. It is a good thing not bad.

How is the honeycomb bonded to the extrusion?

The honeycomb is pressed in, and would require the bow to be beyond extreme for the roof to come out of the extrusion. We have driven a camper through Baja with the roof open and l the way up. After donuts, whoops etc we had nothing more extreme than the slight amount of bowing some people see so there really is nothing you could do to your camper short of taking the roof off and apart to get the Plascore out of the extrusion.

Thanks for the info. My bowing seems to be improved as the tent material softens. I haven’t measured so I don’t know for sure, but it looks improved by my estimation. I’m not currently worried about it. I’ll continue to monitor…

Peace.

Did you ever try hitting the extrusion with a rubber mallet like GFC mentioned? If so did this correct the issue or is it still there the same. I realize this is an older post but am curious. thanks in advance

I hit mine regularly to get it back into alignment but it doesn’t affect the bow in any way.

Don’t pound down on your extrusion. I don’t believe anything good will come from that. A rubber mallet can be useful to realign the top tent portion with the floor portion of the tent laterally. With pounding down, one risks a miss causing damage to the composite top too.

Peace.

Wonder what happened to the video as it’s gone?

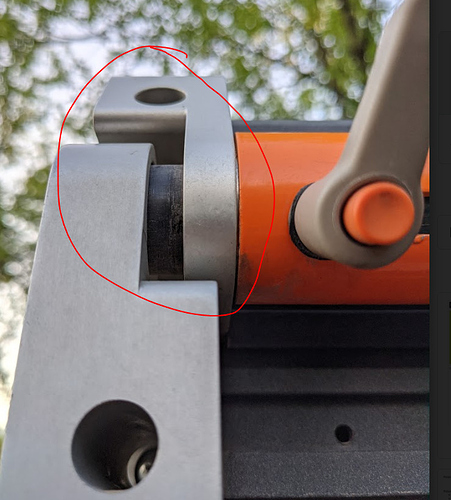

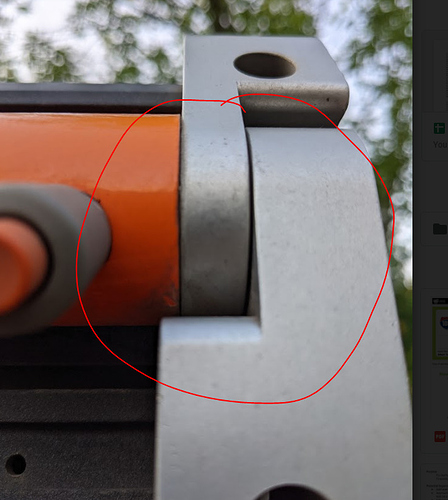

I definitely experiencing this bowing but does it cause this kind of offset? Also, this offset doesn’t seem to affect the front hinge which makes me think the tent is closing in a twisted manner. Could this be a risk to the front hinge?

(driver side)

(passenger side)

I agree. I have had the v1 tent (build 162) for 2 years now and it’s still a bit difficult.

Mine goes out of wack like that. I just wack it over with the dead blow every few months. That was what the GFC video said to do.

Thanks for your confirmation.

I do the same, rubber mallet has worked for me

If you run into this issue while out in the woods and don’t have a mallet, you can also fix the issue just by opening the top a bit and jostling the tent section one way or the other. Super easy to fix.

That was my workaround until I got that mallet