Goal was to build a fairing of wood so that wind noise is decreased, plus possibly improving gas mileage. Secondary goal was to build fairing on the cheap, using some scrap wood if possible…total cost ended up being less than $60. with a lot of left over materials. Third goal was not to spend big money on a metal support rack to support a fairing (and add more weight to truck). Finally, wanted to approximate the ideal angle (about 20 degrees) if possible; ended up using 30 degrees for fairing angle because saws I have are limited to 30 deg. Yes, I know it’s laziness- could’ve use a protractor and beveled square but would’ve had to cut supports by hand.

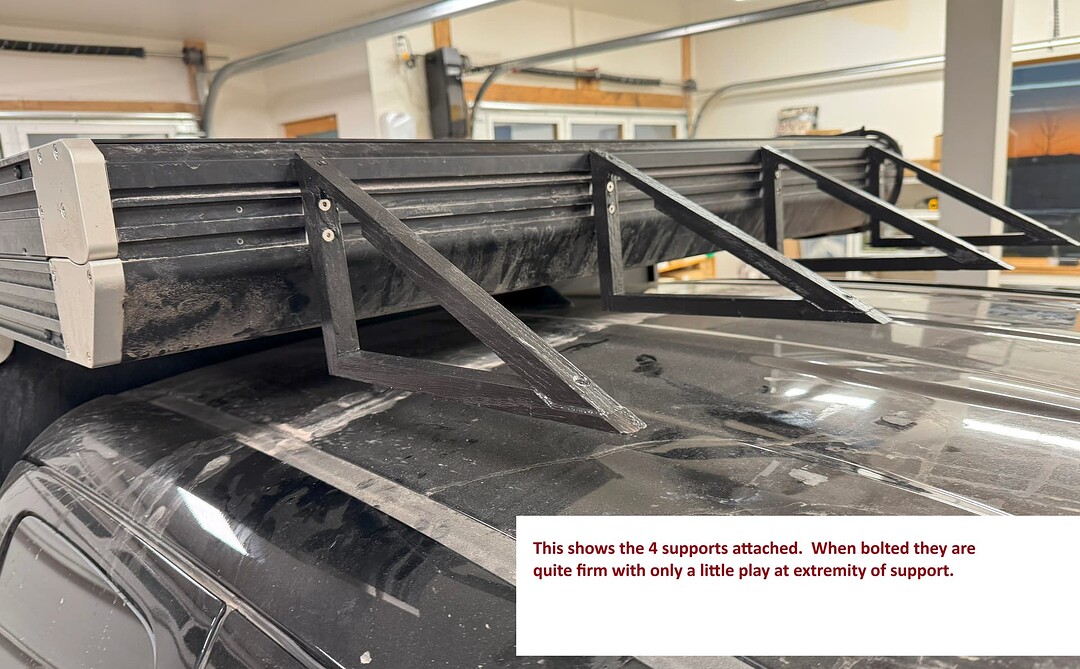

Major parts are: 3/4 inch plywood fairing, hardwood (oak) supports (4), rubber fitting for top of cab, t-nuts hardware.

Bottom line, it works and reduces wind noise significantly. No idea about mileage. It appears to be sturdy, rigid and possibly will last; it’s too early to tell. Using 3 coats of semi gloss exterior paint should allow for multiple washings and wear and tear. There was squeaking where fairing met roof so I placed 2 rows of Gorilla duct tape between rubber and top of truck cab; the tape has a different texture and eliminated squeaks. Note: at first I left a gap of about 2-3" between fairing and cab top because I thought maybe that sizeable gap wouldn’t be important, but found that the air whooshing through the gap was worse than having no faring at all. So an extension was built and attached to the original faring with a rubber pipe insulation section placed so the extension contacts the cab.

Materials:

3/4" exterior grade plywood, 5/8" exterior plywood extension for smaller section contacting cab.

hardwood for triangular supports. I used red oak but would’ve used white oak or maple if I’d had it on hand

t nuts and bolts of correct length to attach to GoFast

wood screws and machine bolts to attach faring to oak supports

washers

use allen head stove bolts with tnuts so they can be very tight

Build process:

- make a cardboard template, ensure the template contacts top of cab roof

- cut out and paint 3/4 inch plywood using template

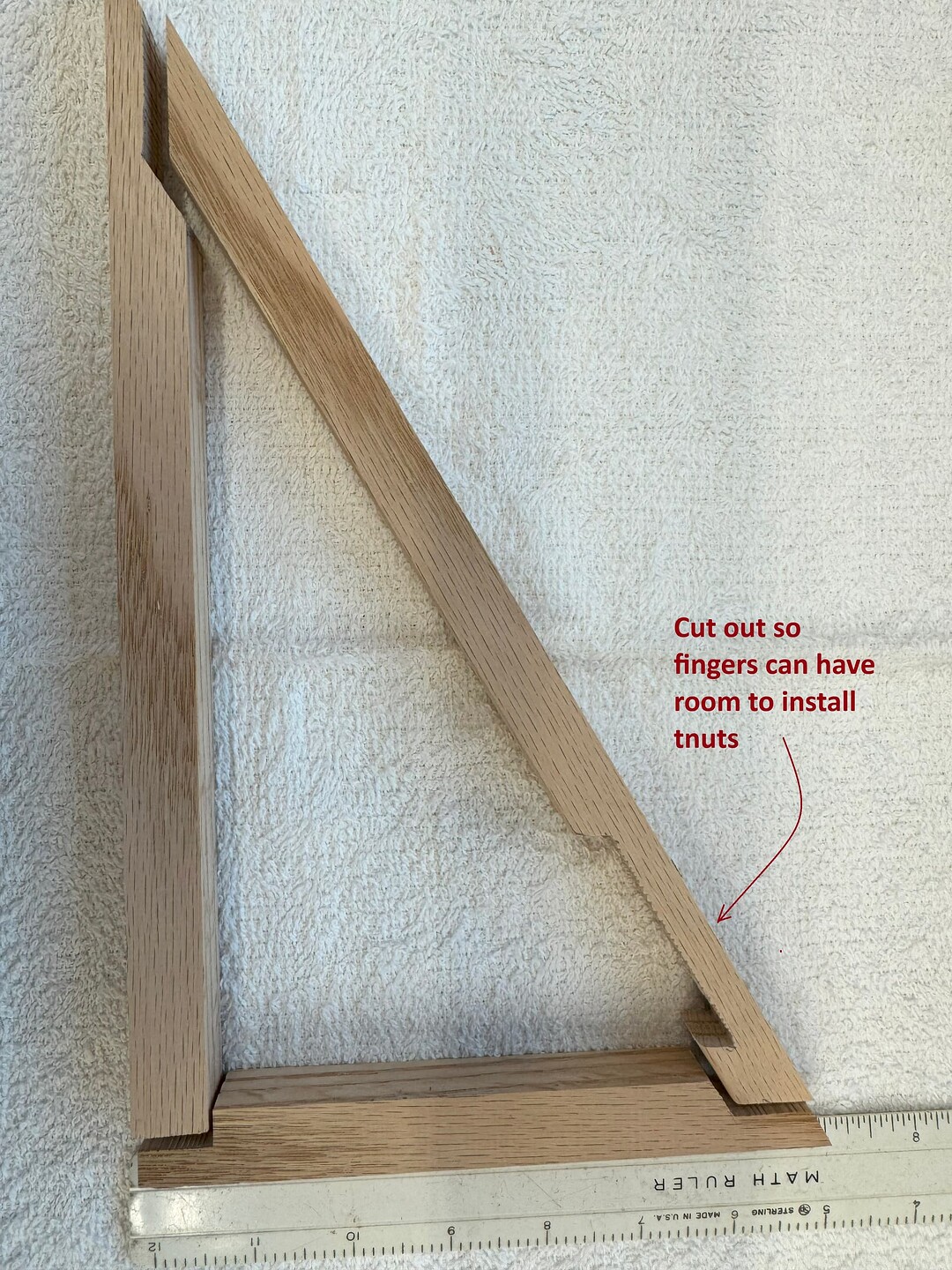

- build 4 hardwood supports with size shown. The triangle is a 30/60/90 right triangle.

- predrill holes in supports and cut away part of support so fingers have room to install tnut/stove bolt

- paint supports

- install supports with tnuts and stove bolts about 1" long. Bolts can’t be too long, nor too short. If too long bolts won’t tighten and will hit metal slot material on GoFast t slot.

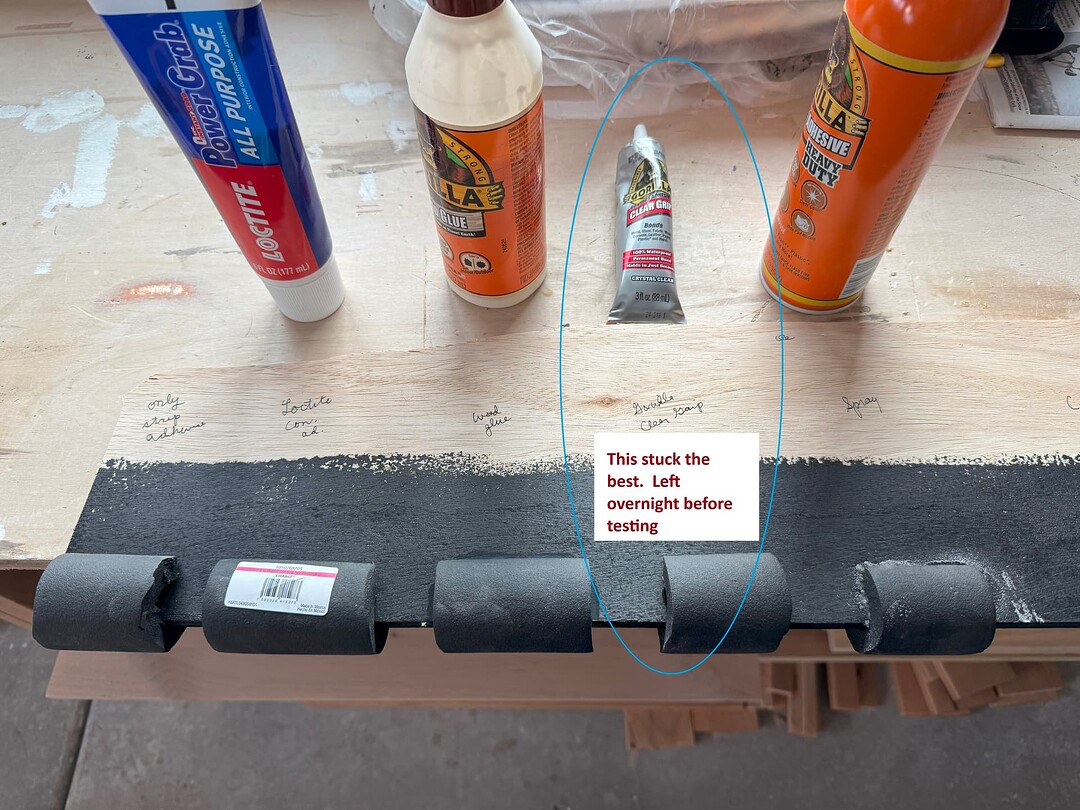

- attach rubber (not foam) to bottom of fairing. Get foam pipe insulation at Home Deport of similar. Used rubber because possibly more durable than foam.

- attach duct tape or VHB tape to rubber where it will contact cab roof

- attached fairing to supports. One trick is to tack fairing in place using a pin nailer; just two pin nails will hold in place until stove bolts are tightened

- fill any countsunk holes and apply touch up paint

- go camping and have fun in your quieter GoFast!

Comments and criticisms welcome of course. Excuse the pictures with dirty vehicle; it’s winter in Colorado and impossible to keep a vehicle clean.