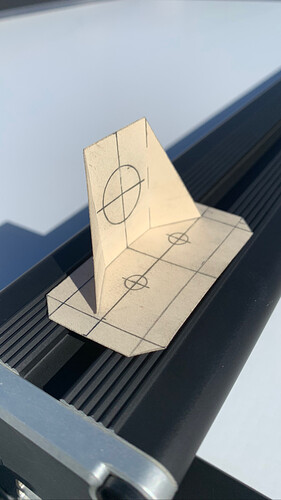

Having a hard time properly tying stuff down to my beef bars, GFC doesn’t offer a type of eyelit or tab for them, Im making a tiedown mount, something strong enough you can crank on with a ratchet strap, it will bolt to the bars with (2) 1/4" GFC track studs

Prototype is made of cardboard, then will be drawn in the computer and laser cut, then up for purchase

Upper tab will be welded to the flat tab and both be made out of 3/16" steel

Feedback is appreciated

4 Likes

Looks great to me!

I don’t have beef bars yet, or any other roof bars… or a GFC yet (I am awaiting install next year)… but I am already doing my research into how I want to mount stuff to the GFC & inside it.

Excited to see the prototype in metal. Cardboard ideation looks great!

1 Like

Looks good. I am interested!

1 Like

Thanks guys will have some cut out of steel later this week

This is relevant to my interests.

i have another idea for you as well- Turn the raised tab 90 degrees so it can be used as a side “stop” on the beef bar. I use my rack for lumber and sheet goods a fair bit, and it would be great to have a stop at the ends of the bars to slide lumber against when loading.

2 Likes

Really, really great idea!

1 Like

Definitely have thought about rotating it 90 degrees the problem is, im really limited with bolting options with these beef bars, until I figure out a stronger and cheaper alternative to the track studs. Track studs are 1/4-20 if it was a 3/8 bolt I would just use one and you’d be able to rotate this tab in any orientation. I feel like this mount will need to use (2) studs for strength

It’s not considered safe to use tie downs with hooks on a roof rack. If the strap loosens, the entire strap can come off. The best way to tie down roof loads is to use an endless tie down (ratchet or cam) and wrap the strap around the bar, over the load and around the bar on the other side. This is the proper way to tie down boats, skis, lumber, etc. The strap can’t come off and you get the entire strength of the bar, not just a bolted point. This is why we don’t sell or encourage using bolted tie down points on the roof.

As for end stops, these are totally unnecessary and somewhat of a nuisance as they hang up on stuff that you might want to slide up onto the bars (handy on tall trucks). That’s why we designed the ends of the beef bars to be relatively smooth. If your load is properly tied down it won’t be able to slide off the end.

1 Like

Right. My post was about a creating stop for loading the lumber only to be used while sliding it up onto the rack, which would provide a positive stop for the first few board or sheets to line up against. I would not use them for securing the load to the bars.

I use the endless ratchet straps (for lumber) or cam straps (for lighter stuff like kayaks) to secure to beef bars.

1 Like