Two of my metal scrapyard projects so far. Put together an video of my first night with the gfc and how I built out my bed slider. Stoked on the results. The slider is rated for 600lbs fully extended.

I made a dual slide for my fridge and stove. Main slide is 40” and the stove box uses a 32” slide.

Originally, I was going to have a powered water source, but later decided it would be more versatile having it portable.

I was able to use the slide base to support a platform over the other side of the bed.

We build custom mods with aluminum extrusion however we don’t use 80/20 for a variety of reasons. 80/20 is an OK product, we just think our industrial-grade system is better. Check out our work at 4WD-Mod.com and Van-Mod.net.

Using 8020 for cross bars for a roof rack, I drew up and had send cut send laser cut 1/4" aluminum mounting plates to attach bars to the t track on the tent. Cheap, and strong. I can stand in the middle of a cross bar and it flexes no more than a 1/4", I weigh 165lbs.

Nice Boston sneaking into the picture.

I did a similar mod for load bars but I left 1" of the plate sticking above the bar. Not as aesthetic but very useful to ensure a lashed load has a stop.

Nice work.

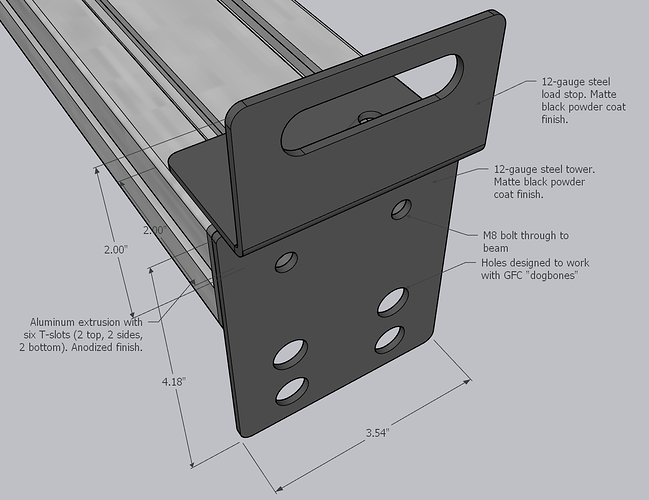

We have a similar roof rail system design using aluminum extrusion but don’t use 80/20. Towers are powder coated 12-gauge steel and designed to work with GFC T-nuts, bolts and “dogbones”. Extrusions are capped, sealed (no water intrusion), and physically separated from the towers. Load stops are 1/8” powder coated aluminum and can be located anywhere along the rail beam T-slots. Products - 4WD-Mod.com.