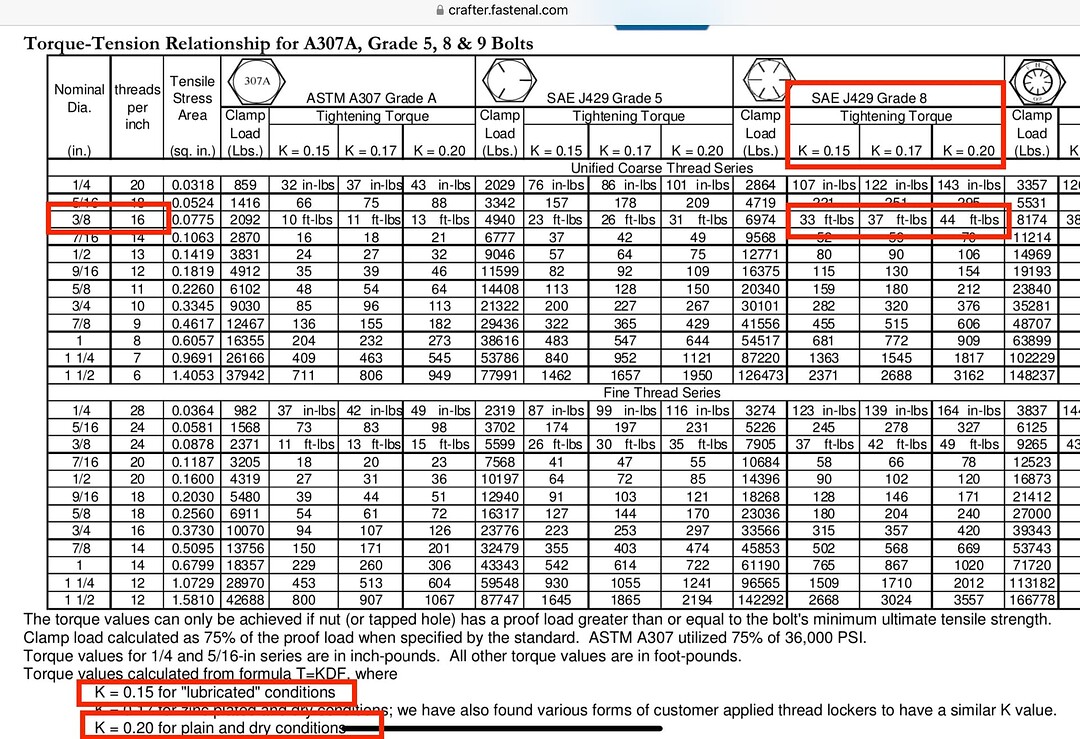

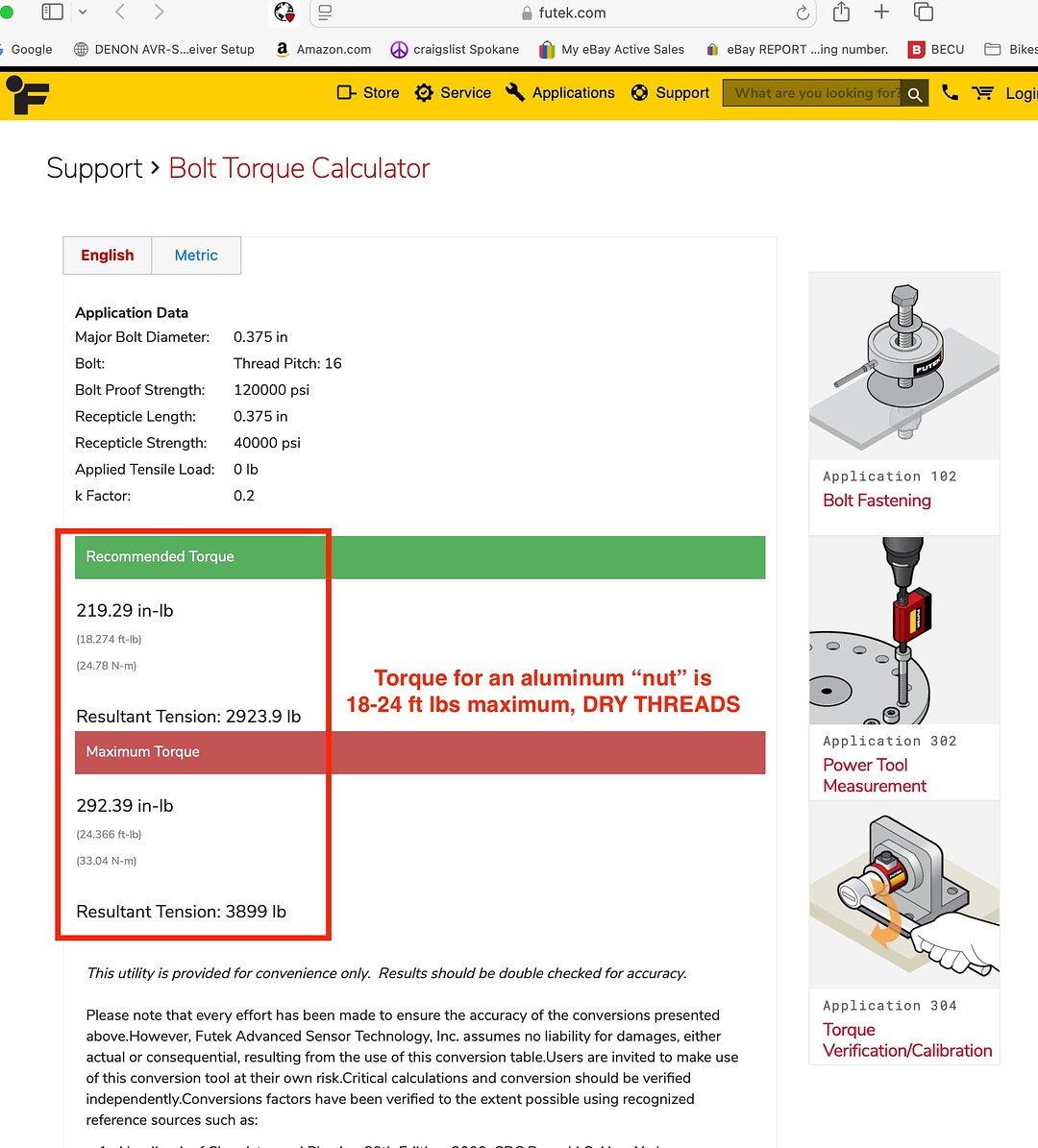

The recommended torque spec is 40 ft lbs for these new style clamps. It is specifically listed as such in the GFC Owner’s Manual and in their YouTube install video. I am unsure how GFC came up with that number. It is appropriate for a Grade 8 steel bolt and a matching STEEL nut, it is not at all good for an aluminum nut plate, even one made of a stout alloy like 6061T6. I don’t know what they use, but I am sure it is strong. A correct DRY torque for this situation is 18 ft lbs (up to to 24 ft lbs maximum).

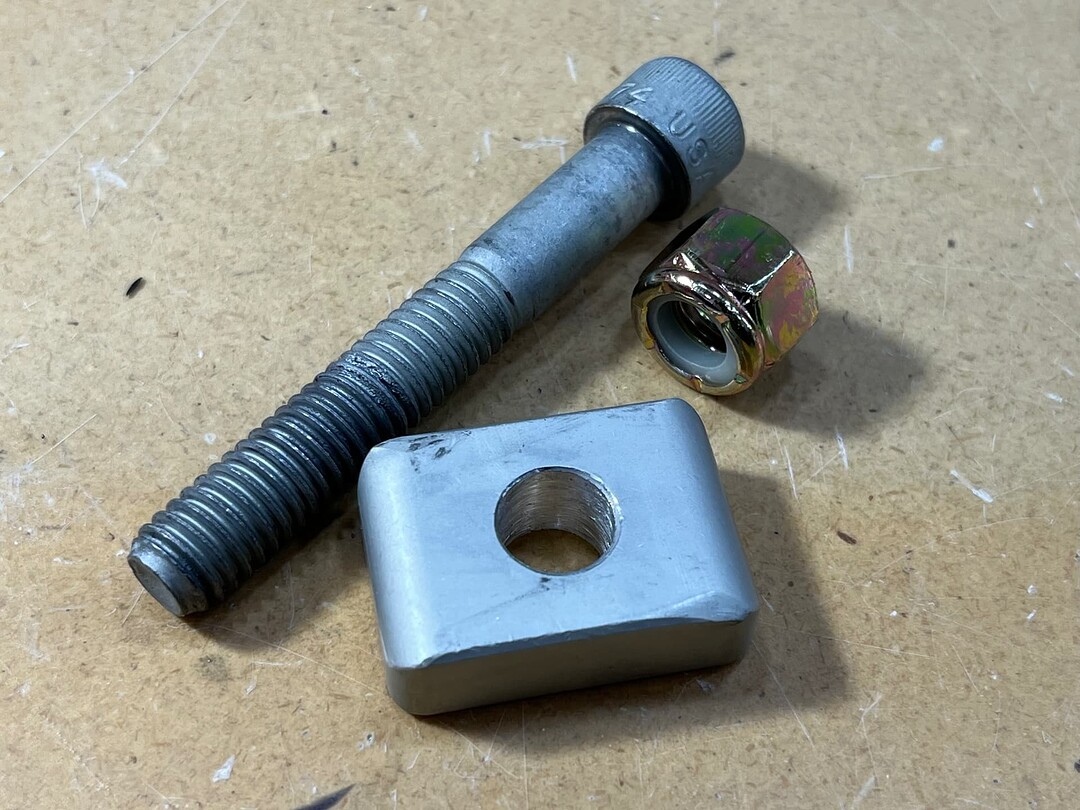

I removed my Topper to reseal the leaking stake pocket covers on my Ranger Raptor, and when reinstalling it with anti seize compound and 30 ft lbs, one nut plate stripped completely. Yikes! That is a sickening sensation… So I drilled out all four aluminum nuts large enough to remove the remaining threads and installed Grade 8 nylock nuts and washers underneath, with silver aluminum antiseize and 30 ft lbs torque.

Now I can hold the head stationary and turn the NUT using a wobble extension and a standard 9/16" socket. And I don’t have to worry about one of the clamps failing when far away from home. Any small town hardware store has the bolts and steel nuts, but a new aluminum nut plate has to come from GFC!

If yours strips while in the boonies, you can definitely just put a nut on the bottom without drilling out the hole further. That should be considered to be an emergency repair, fix all four properly when you are able. It would be prudent to just buy four 3/8"-16 Grade 8 nuts now and put them in your emergency spares kit. Mine were $0.65 each at Ace Hardware.

FYI:

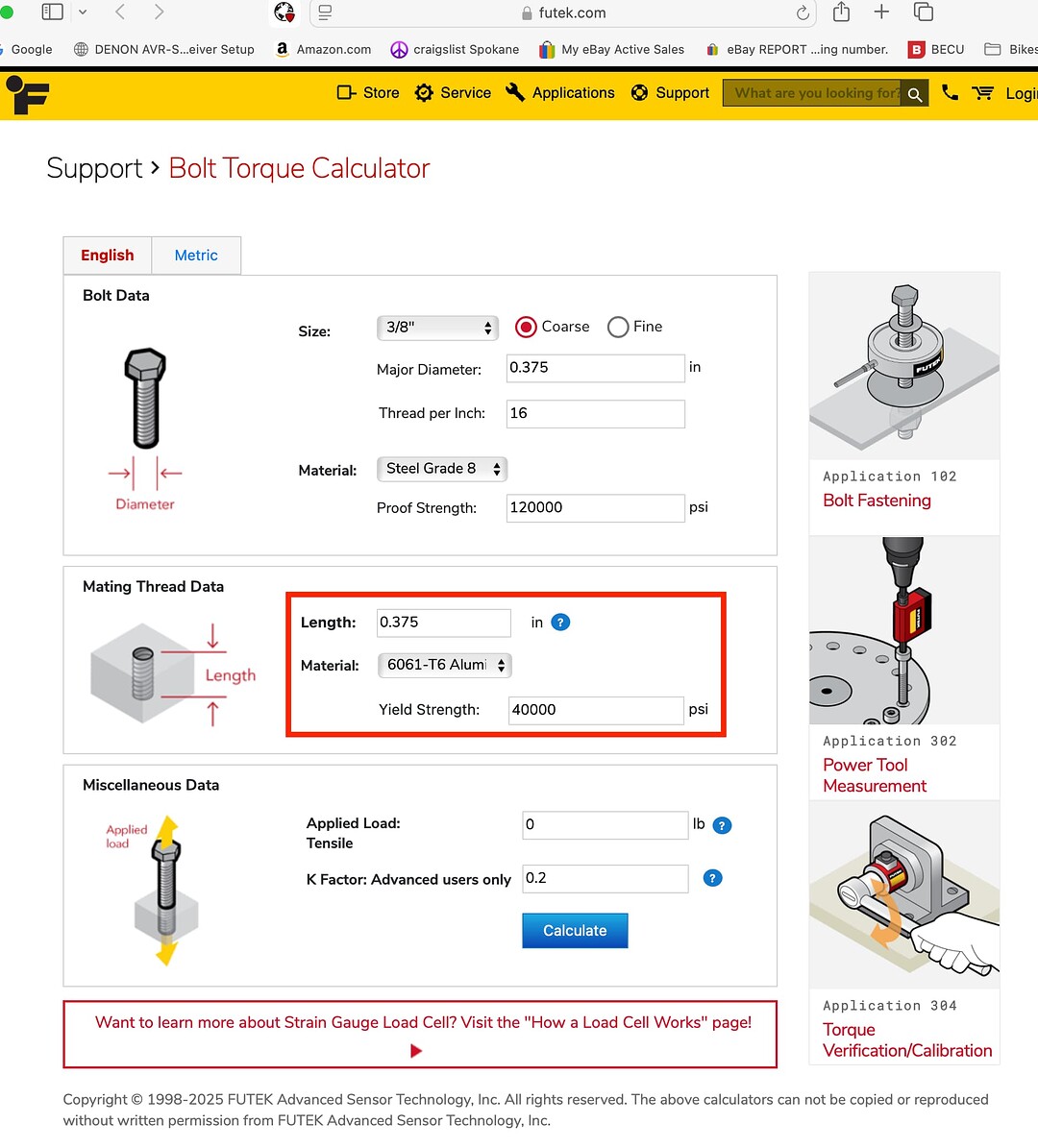

I did not measure the nut thickness, it “appears to be” 3/8", so that is what I used here:

Link for the Bolt Torque Calculator:

https://www.futek.com/bolttorque/american

Has anyone else had a failure or heard of one?

John Davies

Spokane WA USA