Is anyone experiencing this with their beer bars?

Right on thanks for the reply.

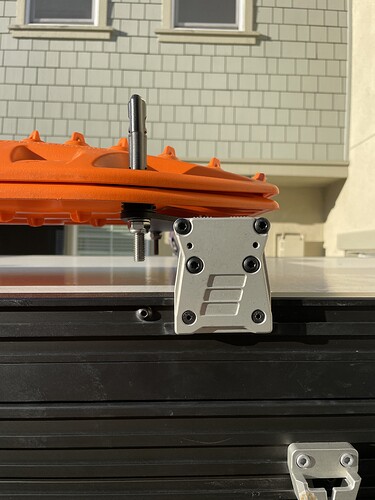

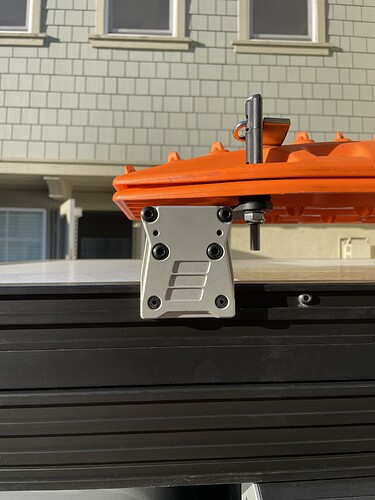

Interesting that the screws are Torx and the bolts are hex.

What kind of pads to you have on your bars? I’ve been looking for something that will fit. Thanks!

I added some xtra Velcro to the pads to make them fit. Also I reached out to GFC and they are sending me 4 new towers under warranty. Super helpful stoked on their customer support. Another reason to get a GFC.

Man that’s a bummer! Hope GFC can help sort you out!

Those harbor freight allens are real good at stripping bolts. I finally bought a set of Bondhus ones from Fireball Tool and the difference in how tight they fit is amazing. Probably wouldn’t have helped in this case anyways, but worth the price.

The fastener has a thick black coating on it to minimize any corrosion build up. So you can insert the drive of the Allen key into the head of the screw and think it is fully seated, but in reality it is not fully seated, so you end up rounding out the head. What I like to do is to take a rubber mallet and tap the Allen key a couple times just to make sure the drive is fully seated before loosening/tightening the screw—I recommend doing this on all our fasteners just to be safe.

As far as removing the rounded screw, take a torx bit, say a T15, and tap it into the head of the screw with a mallet. Then just use a ratchet drive and quickly turn the torx bit so that it grabs into the head and the fastener should back out. This is the easiest method to remove a rounded out fastener.

@GFC_Support honestly, the rubber mallet approach was a game changer! I just did this tonight and all of my bolts tightened much smoother. Otherwise, yes, they round out easy.

Food for thought. I cant find the thread but I know there is one about what people want to know/learn when they pick up their camper. I’ve had mine for 2-3 months. Have 8 nights in it. Love it.

This last weekend camping in the mtns on some good dirt I realized the bolts holding my hinges were loose at the struts. Had no tools with me so tonight I went thru all of the smaller allen bolts on all towers/struts/end caps with the above method. I was alarmed by how many of them were loose. Like good majority.

Is this just from break-in or improper torque testing/quality control? Are they not put on with blue locktite?

I think a good user manual of all bolt sizes, torque, frequency to check things, etc would be absolutely an incredible idea that would win over many customers.

Thanks,

Justin

@78westy most of our fasteners have Loctite already on them. We recommend regularly checking your fasteners and hardware to insure everything is nice and snug. If you have any questions or concerns about the hardware that came loose, send us a Service Request Form and we will get you squared away.

The team has been working hard on getting content finalized around a user manual, so stay tuned for that.

Thanks @GFC_Support. I’ll hold off on submitting a request as I don’t think I need anything now. I’ve tightened it all up so I’ll save you some time.

That will be awesome. Love to have digital one we can all keep on our phones while on the road!

Great documentation of the issue. My GFC is pretty new (installed 01 Dec 22) and I had the same issue within days of install, so it clearly isn’t corrosion from weathering. I wanted to move the beef bars and found I couldn’t: rounded out one bolt and gave up before having the same problem. If I had known you couldn’t move the beef bars I wouldn’t have ordered them. I haven’t submitted a service request yet, but I will chime in that this isn’t an isolated problem and it isn’t due to the effects of weathering. Certainly a concern for me as eventually my truck and GFC are bound for Southeast Alaska, which is the veritable land of moisture and corrosion!

Have you tried heat? If they are using red loctite it will require heating the bolts to help break that free.

These are common issues in engineering and manufacturing. Here are some thoughts on the common causes and solutions for small socket head cap screws (SHCS) stripping:

Causes:

- Improper thread fit - It’s important to use the right fit for the assembly of components, most commonly 2A/2B

- Poor quality of bolts - Issues with quality assurance/quality control can result in oversized hex, out-of-specification thread tolerances, or excessive anodized finishes

- Material selection and galling - The hardness of the fastener can be an issue which causes the head to strip. Bolts may seize up due to the use of similar metals, so it’s important to use dissimilar metals or have a finish coating like black oxide to prevent this. Anti-seize can also be used, but only when necessary (don’t recommend).

Solutions:

- Use dissimilar fasteners, such as stainless SHCS with aluminum t-nuts

- Use the appropriate torque specs

- Loctite - Remove with a solvent compatible with the surrounding materials, or use a localized heat of over 250°C for Loctite

- Use an SHCS extractor set, harden Torx bit, or impact screwdriver

- Cut a slot into the bolt with a rotary tool or cut-off wheel, then use an impact screwdriver to break the lock.

These are some common solutions and causes to keep in mind when dealing with fastener bolt issues. Hope this helps!

Best,

-Ron