Here is my latest modular setup. The DC-DC charger, Solar controller and main fuse panel is housed in a pack-out. This will mount against the back of my box or behind my rear seats using the new pack-out racking. This can accept DC from my under hood batters, 2x group 31 as well as a 25amp 120v battery charger mounted in the engine bay for “shore power”. For solar it will take up for a 500 watts or so. It has quick connect plugs for the connections. It also has a USB and 12v plugs / lighting and a fan if needed for the DC-DC.

Shore power box (12v 25a) this will go in the engine bay.

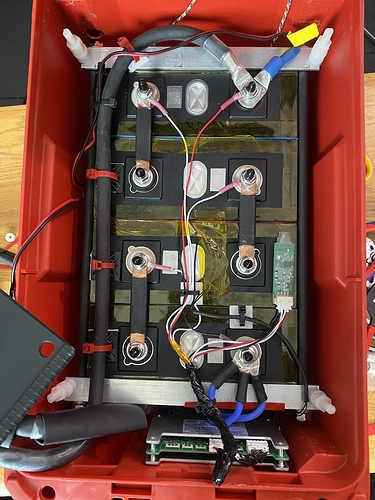

For my “house” battery I made my own from 280ah Lithium cells. I managed to fit this in a smaller Pack-out. This will power my setup from about a week without using the engine batteries. It contains a smart-shunt and the BMS. This can be used stand alone or hooked up to the main unit to charge. It has 2x 12v plugs to run my Dometic GFX3 75DZ fridge/freezer as a stand alone setup. It was super easy to make and about 1/3 the cost per Ah vs. buying a complete battery. Not to mention I know how to service it and can replace the cells if needed for cheap. I do not use a inverter or any high loads so it’s 120a only. The large amp loads will go to the engine batteries. This can hard mount via the pack-out locking trays.

I really like the Victron stuff. I went with it because you can always re-use it for a van build or sell it someday. It is all Bluetooth so you save wiring and can monitor anywhere from your phone. I still do not have my camper (paid a ways back and waiting for information) so the final distribution and switch panel is still in the prototype stage. It will be fed 12v from the main power box or the battery. Something like the photo below.

I just could have got a goal zero and saved all this work but I like to build my own stuff if possible. It’s fun to learn new things and I would recommend building a battery. There is tons of help online.

-Chuck