What is Boogielander?

Boogielander is combination of two words: boogie and overland.

Boogie refers to the act of going fast through desert terrains, especially skipping through whoops, bumps, and dips. Catching air is not required, but strongly encouraged.

Overlander refers to people who participate in overlanding, which is an activity in which participants drive long distances to some remote locations to camp, and often off-road driving of various terrains is required. The process of getting there is a big part of “fun,” while destination is equally important. Modern overlanders are often associated as gear junkies or bougie campers, and I may or may not have the problem of carrying too much gears that I don’t use.

Combining the two concepts, it is easy to see what “boogielander” is: it is someone who enjoys overlanding and boogieing, and I will explain more on that later.

To see how I arrived at where I am today, you can read about my 4Runner build here and why I decided to let it go.

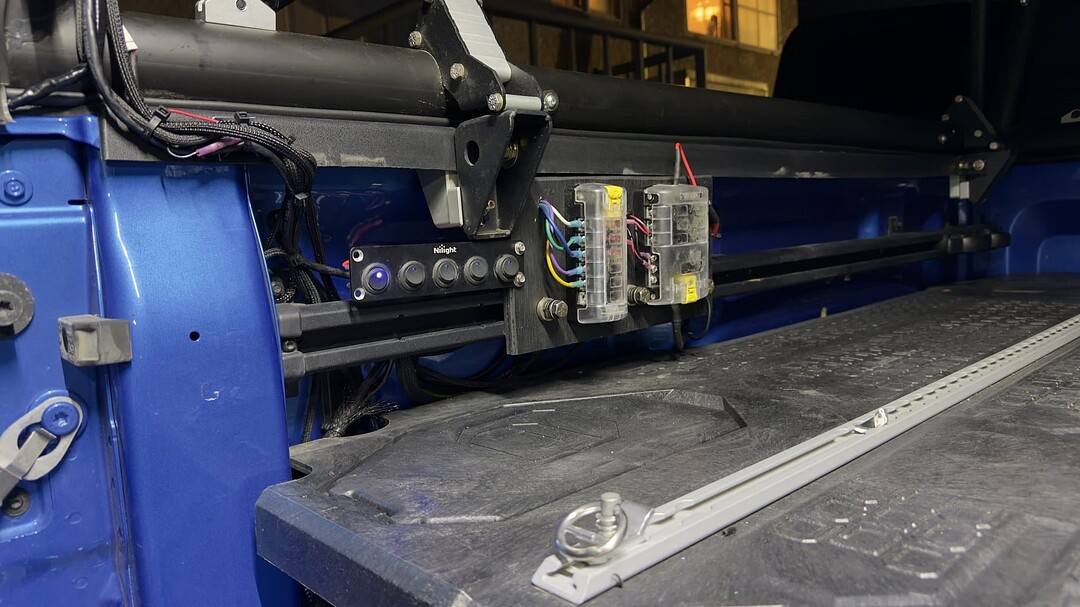

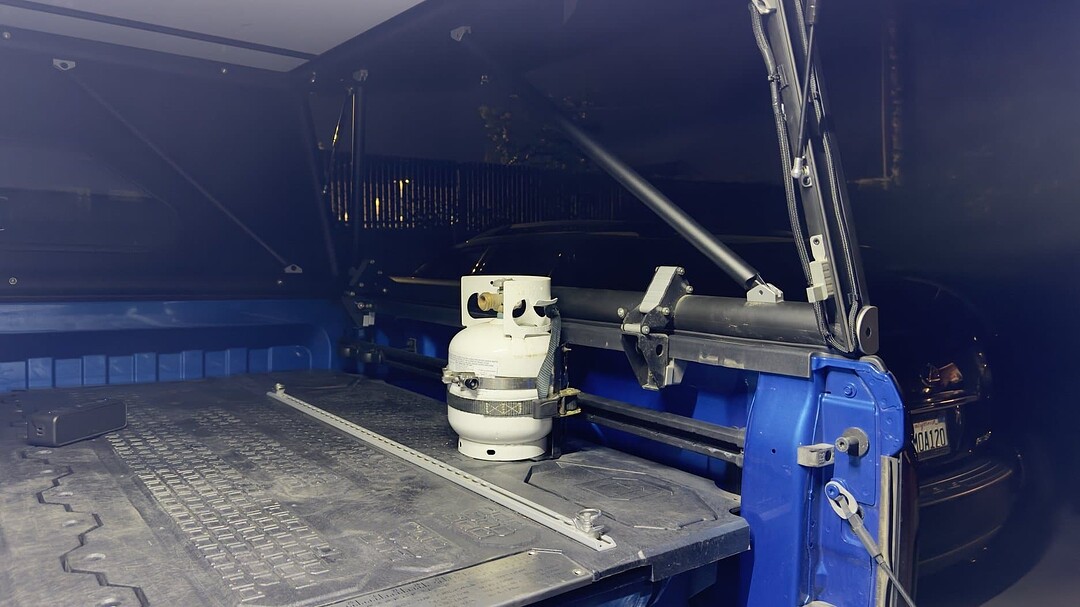

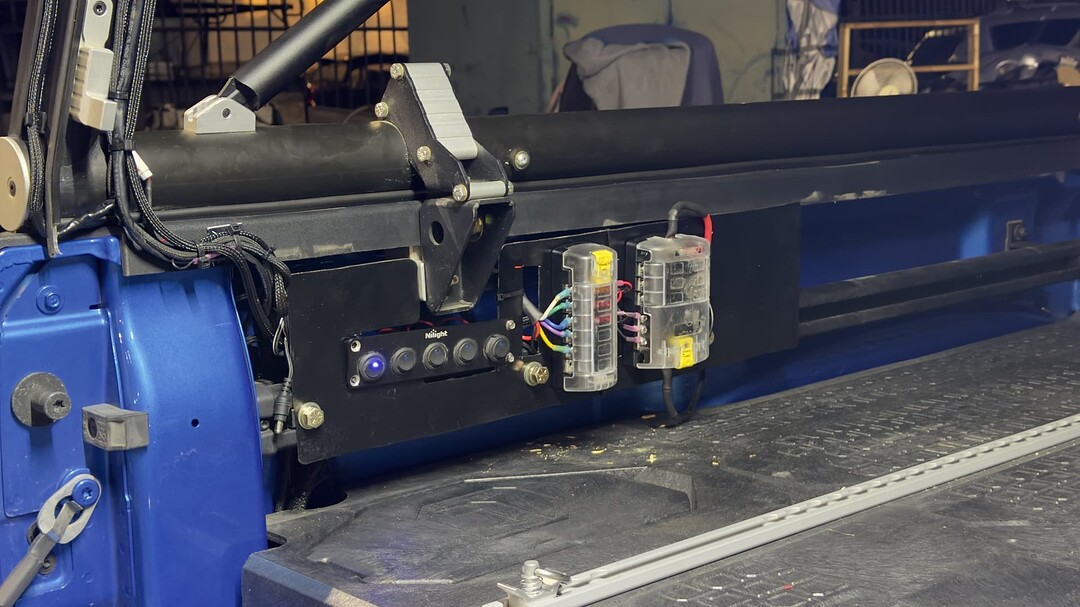

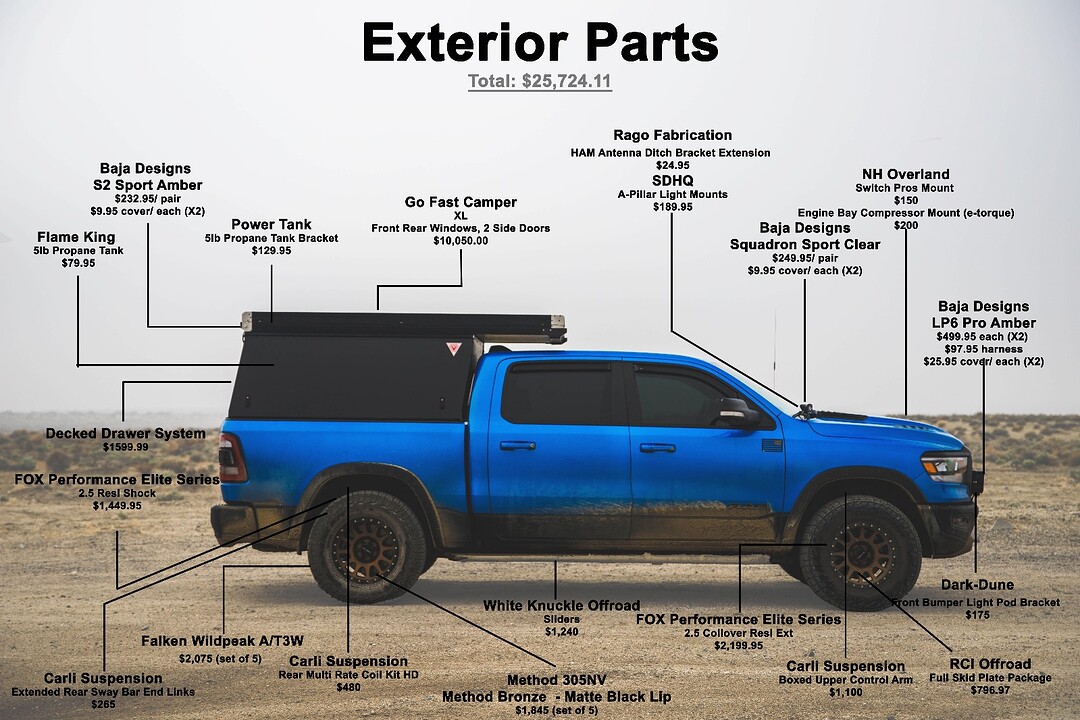

To save to get to the GFC build, you can read about the build here

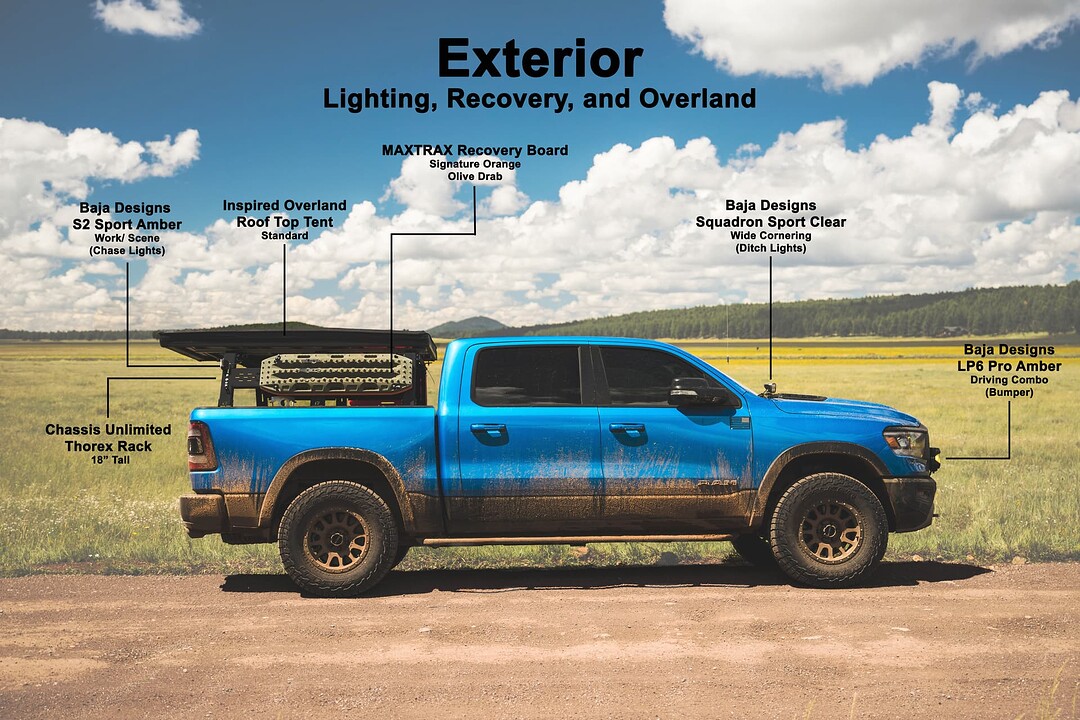

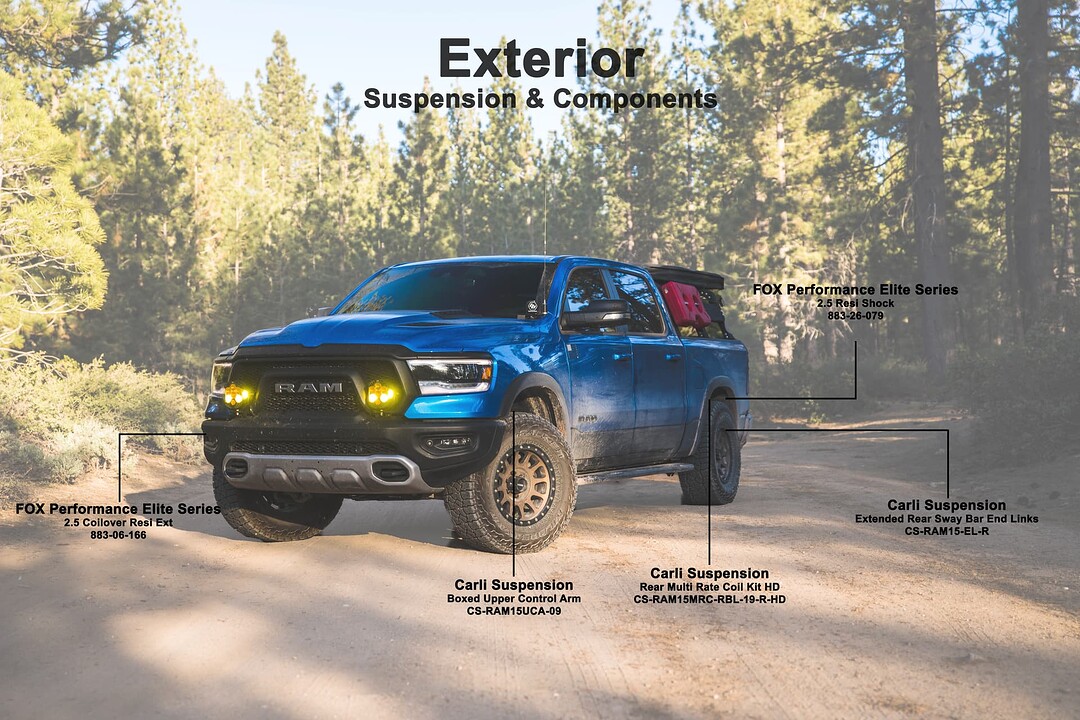

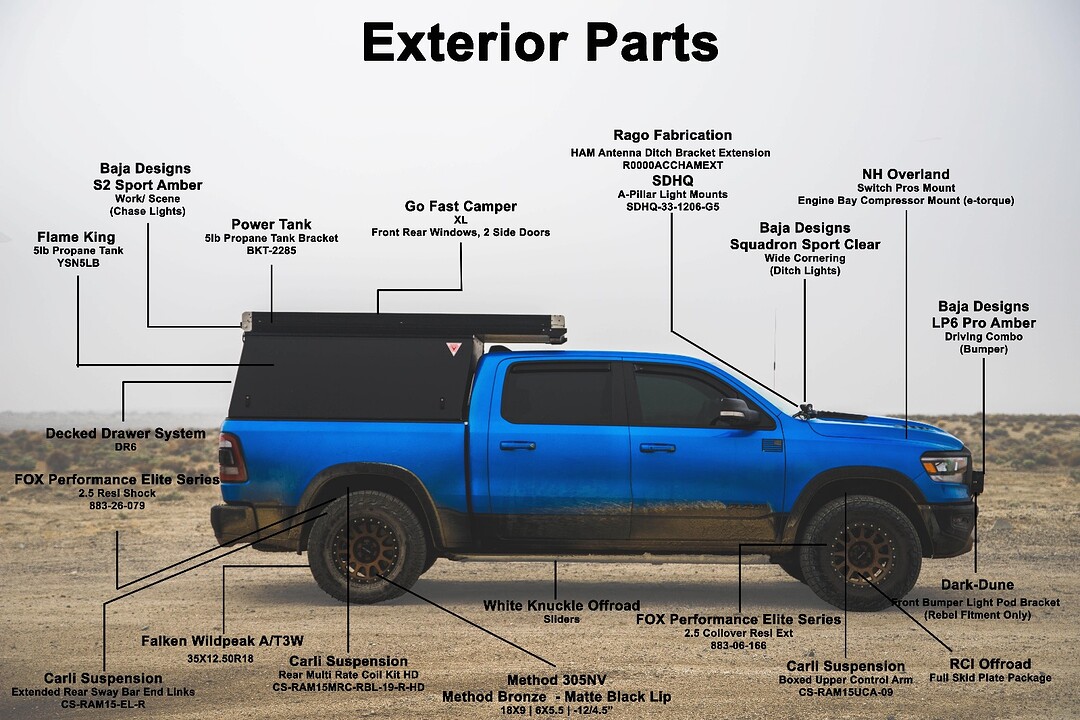

Here’s an incomplete list of mods done prior to GFC (I just need time to create the images):

The plan was always to go GFC since I started the build in 2022, but funding was an issue at the time after all the mods. So I told myself I’d go GFC before summer of 2024, before my planned Alaska trip in September 2024. But one day, one of my customers at the shop expressed interest in my roof tent and before I knew it, hands were shaken and a verbal deal was made. So, I moved up my time table and found @redleader selling his.

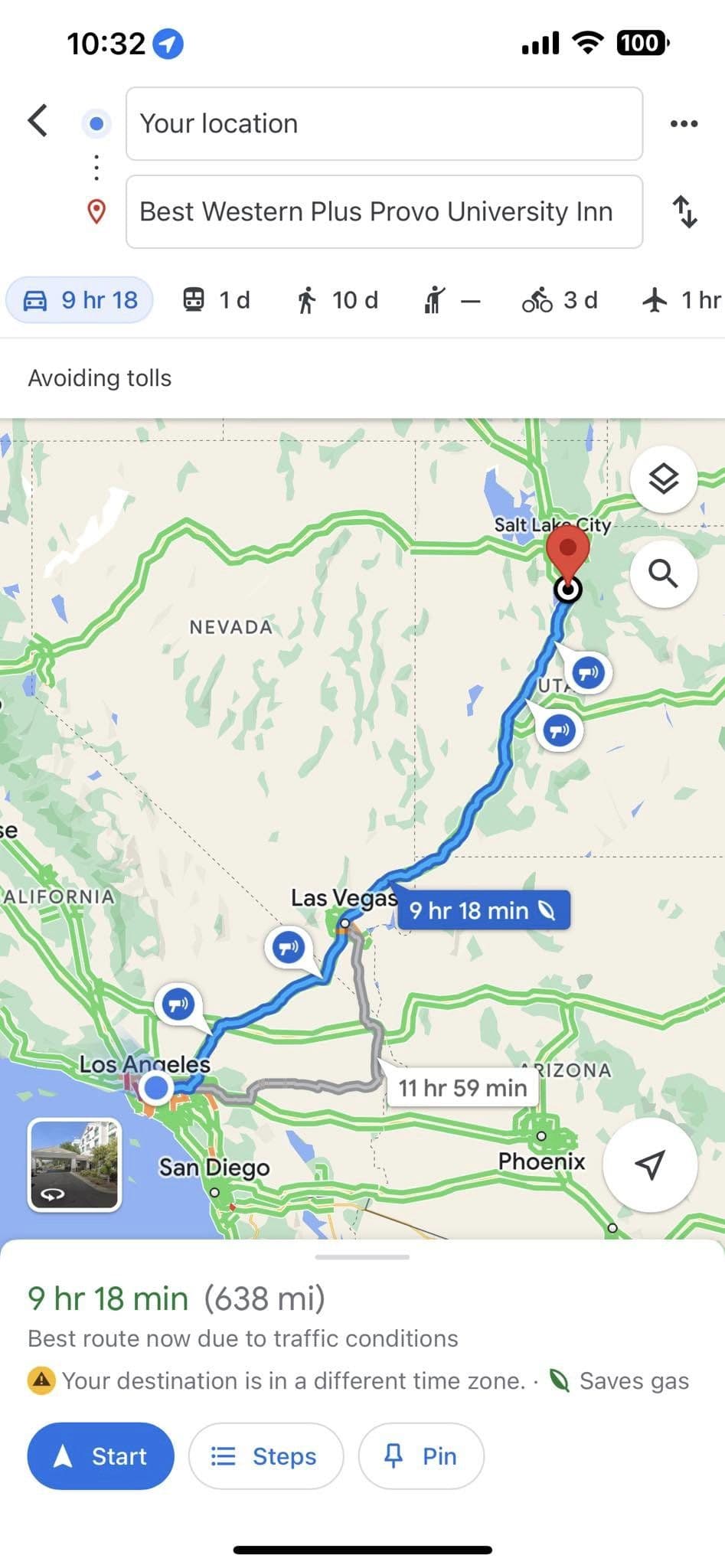

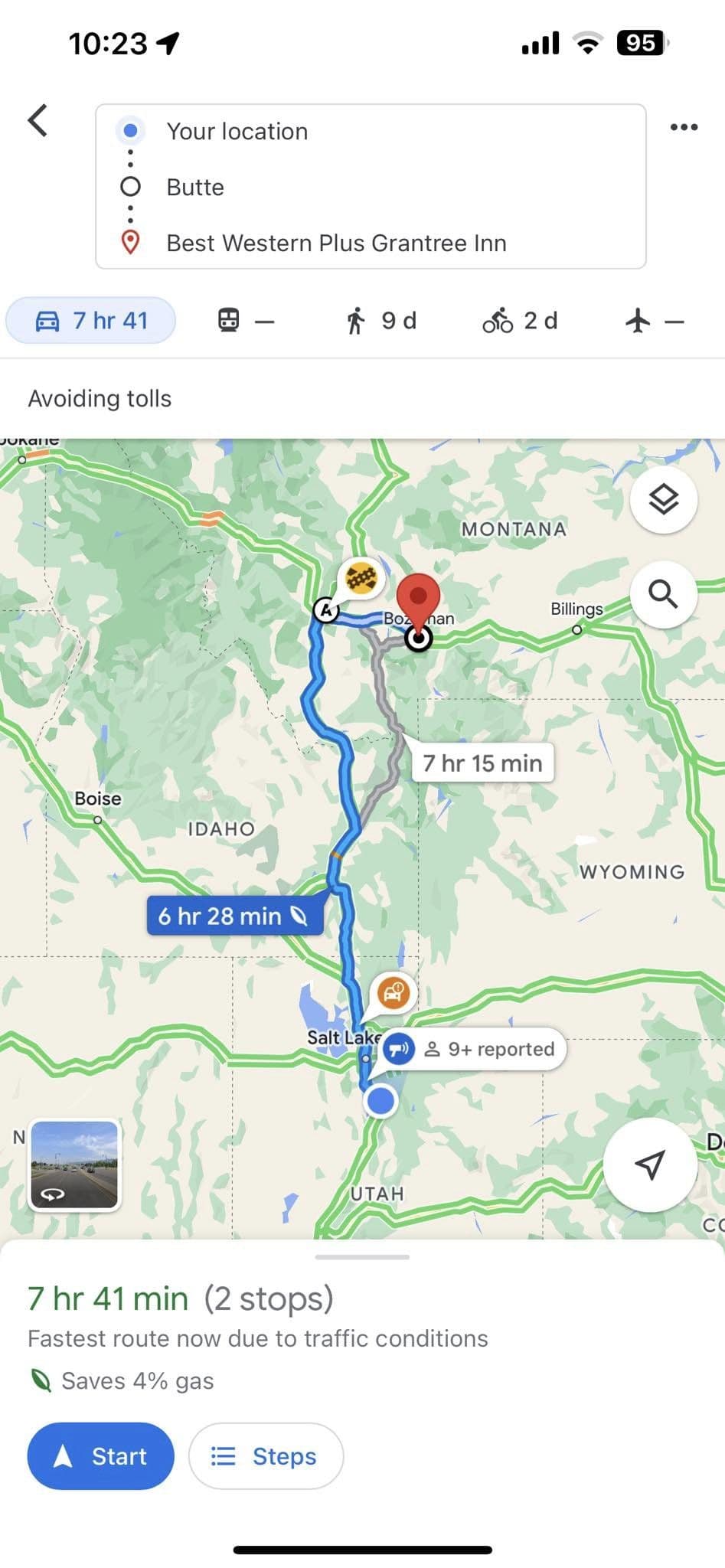

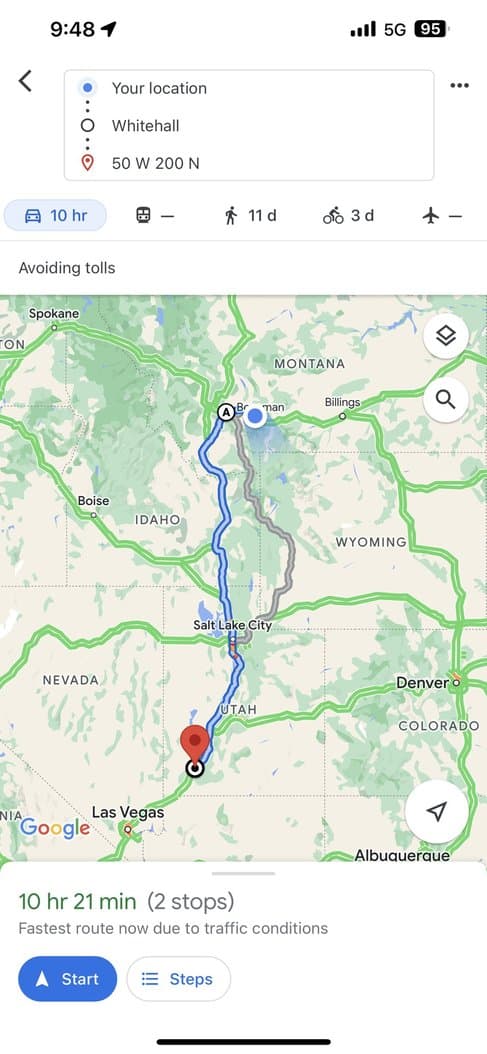

After talking to some local guys and @redleader , I decided to buy Zach’s camper. Deal was made and arrangement made with GFC HQ for install, and here I am, sitting in my hotel room in Bozeman typing this up.

Really excited to start this journey and have inside access to the tent!

*If anyone’s looking for hotel stay in Bozeman, the Best Western Gran Tree Inn is great. Front Desk agent Autumn was really friendly and seems to know who GFC is lol