I do not think handing someone dimensions would work. Fabricator will need hands on fitment in my opinion.

I agree but would like some rough dimensions if possible.

Mine was a straight freestyle design. Measured and welded on the fly. I am picking up on Wednesday. It’s not pretty, but it works.

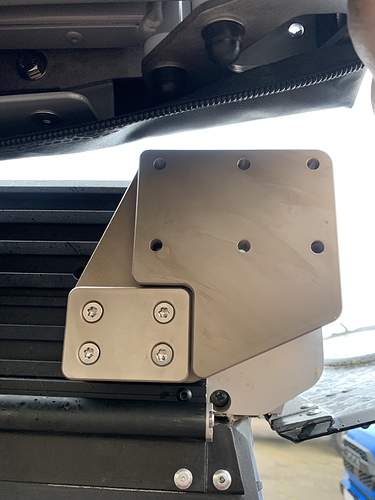

Got my bracket back from my friend. He’s a self taught welder… it’s not pretty but it works. You can really tell the difference. A bracket like this is definitely needed in my opinion.

Just wanted to post an update regarding those small holes in my Kinsman awning that occurred during shipping. The Tenacious tape is holding very well, and Matthew did offer to replace the fabric but it is working out just fine.

Got my bracket back from powder coat… looks like I’ll be needed to have someone design a new one down the road. The new hinge will not be compatible with my bracket.

The AluCab awning is awesome! Mounting it to GFC needs a lot of TLC…

The AluCab awning wants to overhang ever so slightly past the corner of the tent/camper, and the mounting extrusion track stops short of that corner. And as correctly pointed out above - securing that corner is pretty critical.

I was pretty tempted to drill & tap the GFC corner billet with something like M14 (9/16 - 12 in old money) to secure the AluCab awning, or build a bracket similar to what has been posted above - mounting to the back side of the camper. But managing the height, offsets, and various other alignments with spacers didn’t seem appealing to me.

Instead, I figured it would be worth-while to start with a solid chunk of aluminium and design one part to do all the work of attaching to tent/camper, working as a spacer, and an offset that would match GFC awning mount brackets…

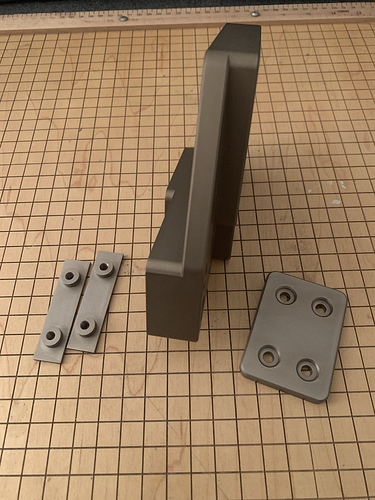

It took me a couple of stabs of getting this one right. Here is the first one in the making.

- GFC awning bracket needs a slight mod. I threw it in a manual mill and slotted a part of the central mounting holes.

- The height based on max allowable by GFC awning bracket - it lets the sides open properly.

- The AluCab awning does stick up past the thin camper… but with Beef Rack in place - it will look dialled in.

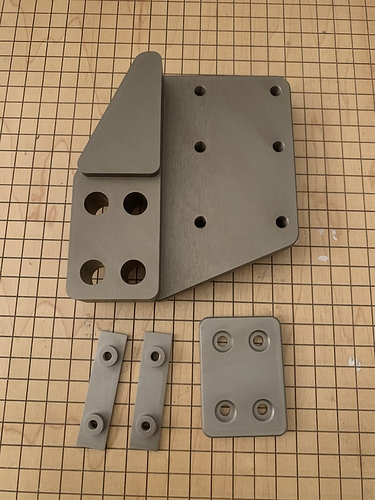

I then made a few improvements, and had the pieces anodized. Once I install on the camper tomorrow, I will post more images. Happy to answer any questions.

First test trip out to Yosemite this weekend, with the prototype bracket.

This is awesome! A very nice solution.

I need one - are you going to make this a little business? You can PM me if you like.

And, most importantly - from the looks of this it should work with the new embassy hinges. Yes?

I’d be happy to make a few extras  The prototype performed well over the few weeks I had it. Next up is some more testing on the revised piece.

The prototype performed well over the few weeks I had it. Next up is some more testing on the revised piece.

Yes it’s designed to work with the new hinge system.

GFC is installing new hinges this weekend, so the awning needs to come off to make it easy to do work on the camper. Will post more photos once it’s all back together.

Here is the 2nd attempt at that corner bracket. I even got it anodized, but in a wrong color, doh!

- 4x M8x20mm bolts to hold the awning to the corner bracket seem to do the trick.

- Corner bracket height works with GFC’s brackets maximum height. Anything lower - and the side panel won’t open fully.

- GFC brackets need to be customized, lower connection point needs to have a slot.

- Works with new hinges

Wow thats awesome… I have an alucab shadow awning and would love to purchase that bracket off you!

Will post up costs shortly.

Do you think you will be able to modify the GFC Bracket as I suggested above or would it be easier if I did that and included it all in the kit? The modification is fairly simple if you have access to a mill - just need to connect two existing centre holes into a single slot to match AluCab’s pattern.

Here is the BOM for total of 3 brackets:

- Corner bracket assembly (Bracket, clamping plate, 2x T-nut plates) - all milled from AL6061-T6, Clear Matte Anodized, with SS316 hardware (I will change it all to SAE thread to be consistent with GFC)

- 2 sets of GFC mounting bracket sets, modified to work with AluCab (so you don’t have to drill the awning)

I could easily get my current awning brackets milled to fit. Could you send a picture of them showing exactly what you mean?

Although I’m sure there are people that wouldn’t be able to, so offer a package with and one without.

That turned out awesome…i would totally buy a set! I see you have Montana plates, I’m in the flathead

Thanks for your patience all - here is where you can find pricing & a way to order. I figure I’d need ~3 weeks to get the first set going.

I will also work on the RHS version.

Couple of things I’d suggest to help with install:

- Get at least 2 sets of GFC Brackets. I am running 2 modified GFC brackets together with the corner bracket. The Shadow Awn is 24kg (52lbs) static. The brackets hold static and dynamic load (assuming 4g) without issues. I suspended 170lbs from the corner bracket alone to verify.

- Get an extra DogBone + 2 T-Nuts from GFC. It will help mount AluCab’s clip that holds the tension rope in place.

This seems like a good place to ask this:

Does the GFC universal awning bracket bolt to commercially available, flat, 3 channel, 80/20 extrusion (like the stuff available on 80/20.net)? I have a camper and wanted to create a modular awning mount by adding a length of channel to the outside, then mounting my awning to that. Thanks in advance!

@alpinerabbit I don’t have the bracket, but work with 8020 a lot (making a pivot swing arm table and folding jump seat in the truck bed right now). I’d be suprised if you couldn’t make that work. Based on what the GoFast bracket is, should be able to use native 8020 hardware. If not with the native 8020 hardware options, there are other tricks. For example, common 8020 trick for mounting extrusion in van builds is to slide a carriage bolt in the extrusion and use washer/locknut to secure to the wall.

Hey Tim,

I’m also interested in Thule Hideaway. Did you go with the direct/wall mount (a sort of hooking brackets) or rack mount (T-slot back awning)?

Are you still happy with your Hideaway choice? Any feedback?

Thanks,

I love the Hideaway compared to my James Baroud awning. The ease and speed of deployment means I use it much, much more often. And it’s just as easy to use by a single person compared to two. I used the rack mount, not the wall mount, and it attaches to the GFC awning brackets easily. I like the fact that Thule sell individual replacement parts for it to in the event I break something.

It comes with a few downsides:

- It’s heavier than other equivalent pull-out style awnings.

- The awning enclosure isn’t a full box like you can get with the JB or ARB awnings.

- The awning doesn’t protrude as far as other pull-out style awnings.