Finally received my FD last week. The UPS guy did not look happy dropping it off!

All the components were very well packed, took me quite a long time to unwrap everything and lay it all out to ensure I had all the pieces. All the hardware was separated and labeled, which was very nice. The emailed install instructions coordinated with the labels perfectly as well, which made organizing everything much easier.

That being said, the install took me quite a long time. If you don’t have a ratcheting end wrench, you’ll want to get one. I didn’t and was still able to get it installed, but it would have been much easier with a ratcheting wrench as opposed to my open/closed end wrench.

The instructions are easy to follow and the figures attached to each section of the directions are well put together. There are just a lot of hardware pieces that take a lot of time to get in there.Overall, the level of handiness is pretty low.

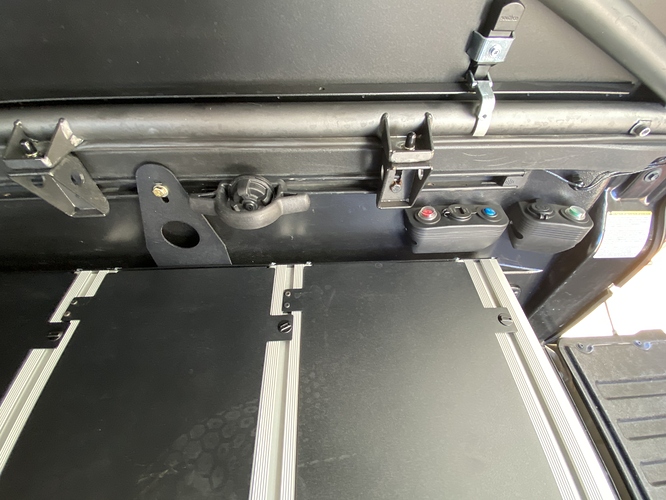

There was only one area that I had questions about, regarding the ‘hold-downs’ (part #200-483). The hold-downs are flat, and attach to the bed rail at the top with a t-nut and the ‘side rail’ (part #200-480) with two flat head bolts and nylock nuts at the bottom. The issue I see is that there is a couple inches between the bed track and the side rail placement. The hold-down isn’t angled to span the gap, and if the top is tightened along with the bottom, it puts stress on the side rail to the point where the side rail bows out between the beef bars.

I tried tightening the bottom bolts first, and then the top and vice versa. Both ways put, in my opinion, unnecessary stress on the side rail. If the hold-down was bent at an angle to span the gap, I think it would mitigate any stress points on the side rail.

I’ve left it relatively loose for now until I get some sort of response back. Otherwise, the initial install took me about an hour. I’d also recommend having a 3/32" allen bit in a socket wrench instead of using a tiny allen wrench to install those bolts, it would’ve been a PITA to use that to install the fake hinges.

I saw somewhere that GFC estimated it would take about 30 minutes to uninstall and reinstall once the FD is put in. I’m interested to see how they think that’s possible and if they could put out a video on their recommended removal and storage of the FD. I think it would still take me quite a bit more time to break it down, especially if it has to be taken all the way down, and I’m still not even sure how it would be stored when not in use.

Otherwise, it looks great in the truck and feels very sturdy when standing on it. I have a 2017 DCLB, and plan on some storage options below with partitions integrated into the beef bars with probably HDPE and some rivnuts. I’ll post some photos up when I get the chance to help anyone else waiting on making a decision, and I’m happy to answer any questions anyone has about it.