Despite 110F temps, this last week I tackled quite a few projects. I installed the Espar AS3-D2L Diesel Heater, wired the DC to DC charging system and shore power inlet. To do this, I had to remove both driver and passenger seats.

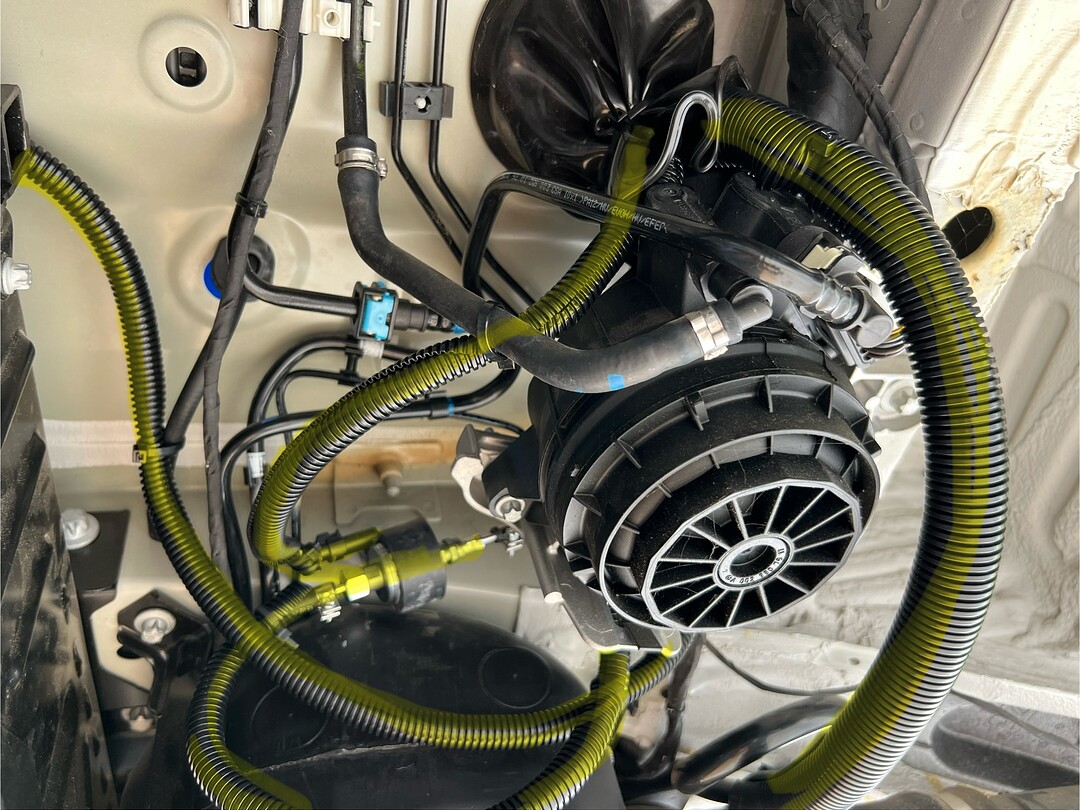

My van came with an auxiliary battery under the front passenger seat. I removed the auxiliary battery and associated wires as it’s not needed. To install the diesel heater I used the diesel heater base gasket as a template to drill out the holes for the intake/exhaust/ mounts/fuel line on the van floor. Once drilled, I deburred the edges and painted Por-15 over the exposed metal. I used high temp silicone at the mounting location to prevent any water intrusion near the exhaust plate. I ran the exhaust, and air intake and used rivet nuts to secure the muffler and exhaust pipe safely to the van.

Mercedes was kind enough to have a Dorman auxiliary fuel tap installed so I used that to tap into the diesel tank. I mounted the fuel pump near the gas tank, routed the wire from the diesel heater to power the fuel pump. I haven’t decided yet where I’m going to place the Espar Easy Start Pro Controller, but there’s enough included wire in the harness to place it anywhere in the van.

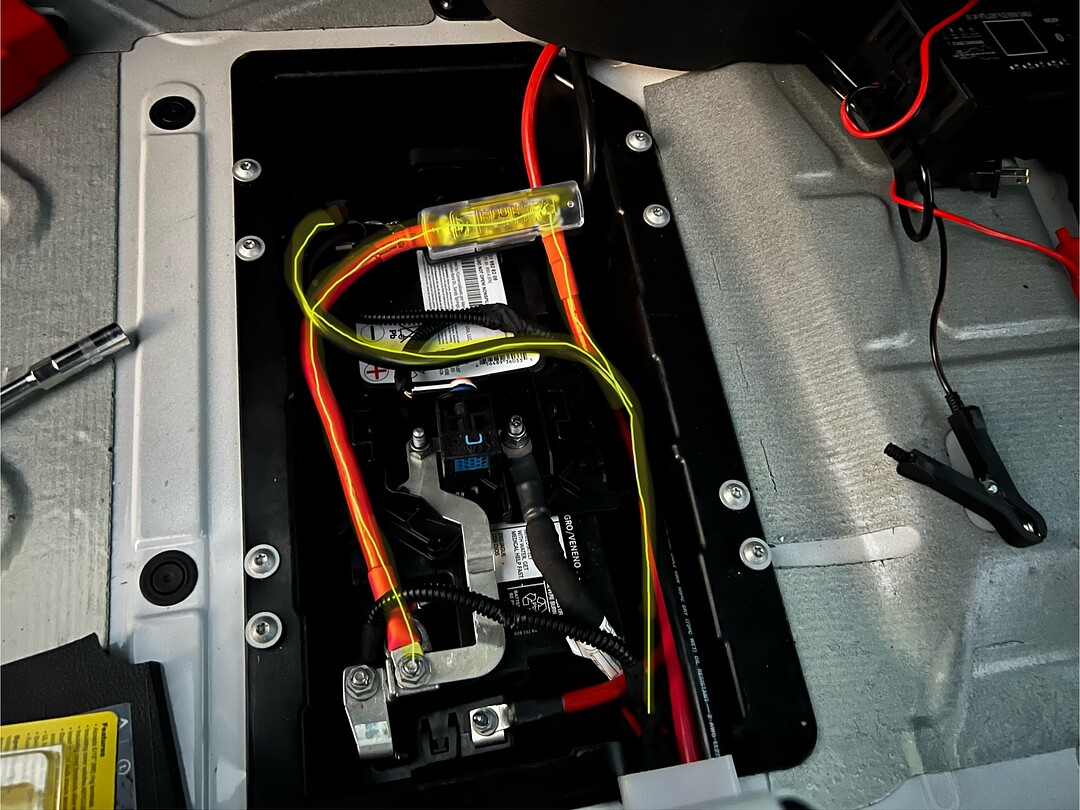

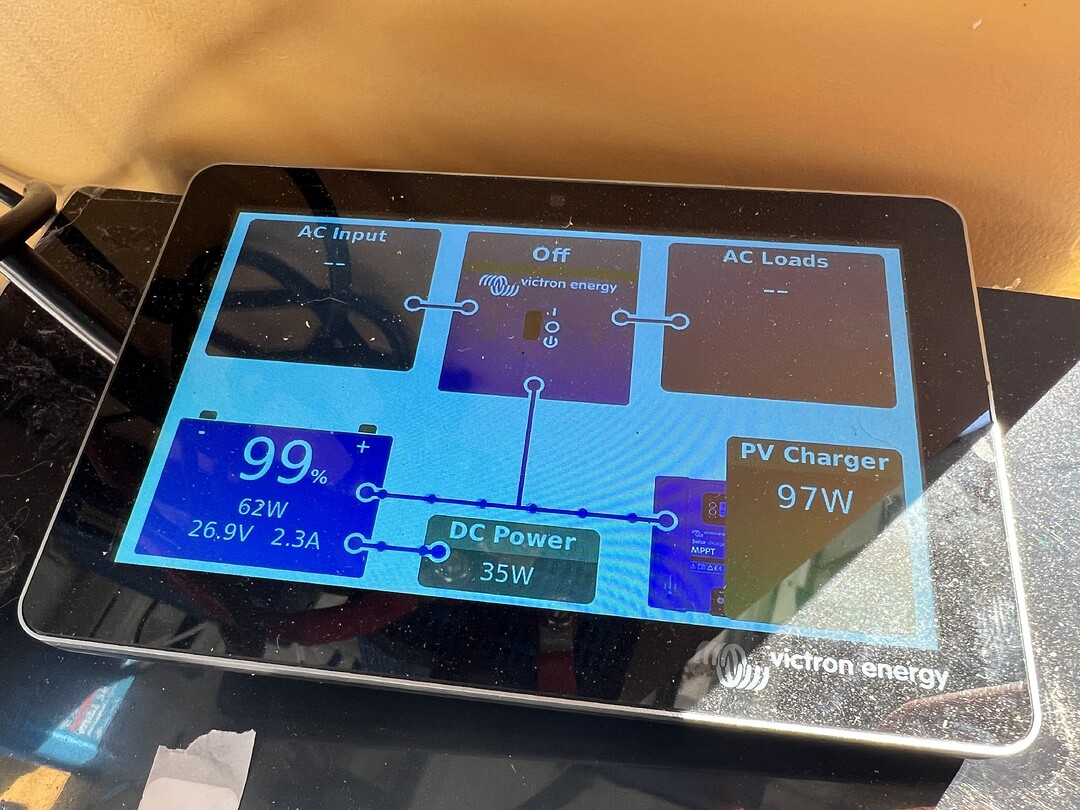

For DC to DC charging, I ran 2 gauge wire from the van battery (driver floorboard) outside through a rubber boot under the driver seat, along the frame, and into an access hole near the driver side rear tire. From there it’ll connect to the two Victron 12-24/15 Orion Smart Chargers running in parallel to give me 30 amps at 24 volts of charging. This system will be fused at the van battery as well as before the Orions and at the Lynx Distributor.

The Victron Multiplus 2 also has a built in shore power inlet. I ran 10/3 triplex wire from the electrical cabinet (Multiplus 2) though the same access hole near the driver side rear tire, along the frame and to the rear bumper. This will give me 30 amps at 120V of charging capability if I’m plugged in to shore power.

To protect the fuel lines and electrical wires, I used flexible split loom conduit.

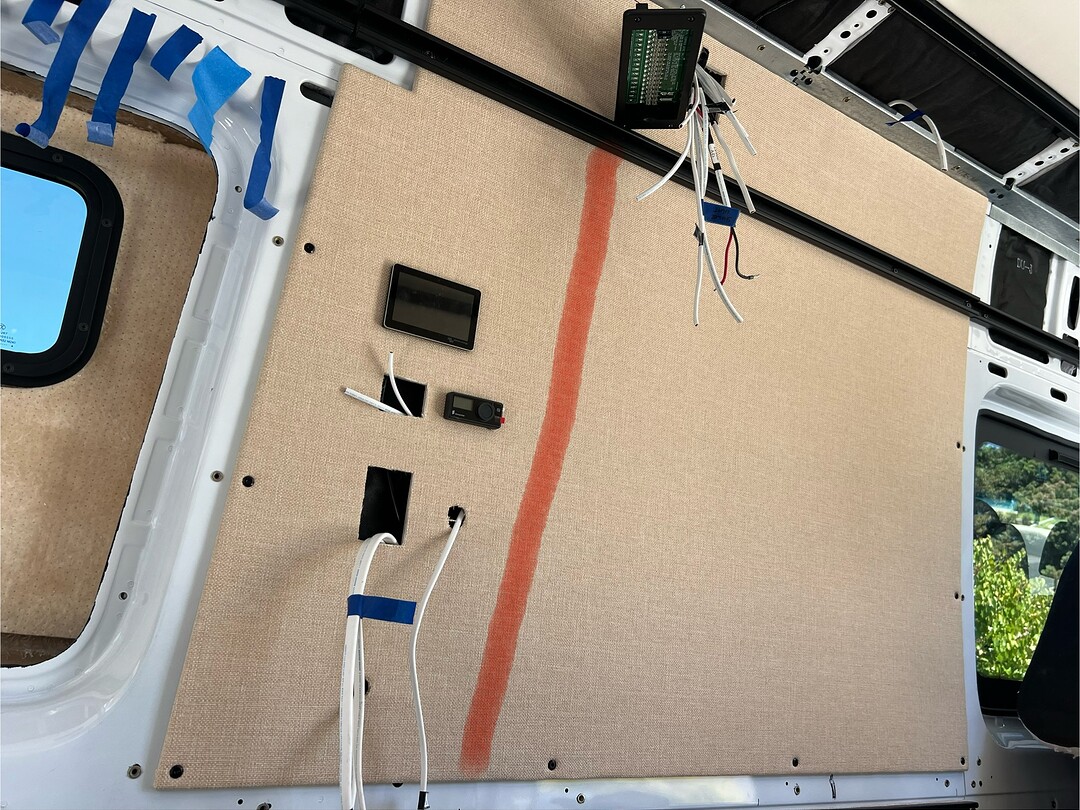

The end is in sight for doing the electrical. I can’t wait to insulate, install the panels