So I’ll ask. What’s with people’s hinges breaking on the panels?

Interesting to hear about the UV factor. I wonder if its a material specific issue that could be coated or changed out for a different hinge material.

Definitely happy to address this.

First off, a tiny number of customers have experienced any issues with a hinge failure, roughly 1%. We have immediately repaired anyone’s camper who has experienced an issue.

There was a comment made that was meant to portray customers have unintentionally broken their hinges by using their campers in a way they weren’t designed to be used. It is also true that we cannot blame them for doing so, as we haven’t officially explained the ideal use case and best practices. So ‘customer misuse’ is not a thing unless we define the ‘use’.

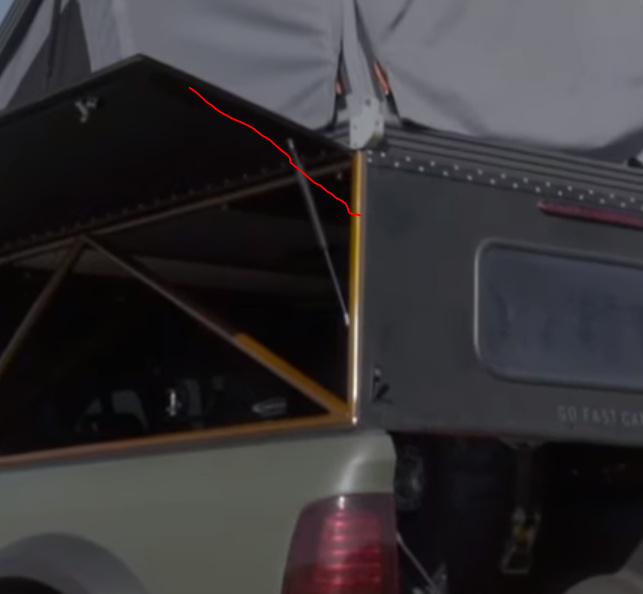

Here is the “misuse”:

We had a few folks that were getting up onto their tailgate by pulling themselves up by the panel corner. So they were grabbing the corner of an open panel from the ground and using it as a handhold to pull themselves up onto the truck. This resulted in undue stress on the hinge and basically formed a starter crack on the edge that then propagated across the hinge line.

We didn’t assume a customer would use their campers in this manner, and didn’t think to address it proactively as it was clear to us (the designers) that the product was not designed to be used in this manner.

The best practice:

The hinges are meant to be closed in an even manner, and care is taken in the opening and closing process. Basically, its a quality high-performance part and it should be treated accordingly. Be careful when opening and closing the panels, and push evenly on the panel when closing or opening. It is something that should never be yanked or forced.

Early Design notes:

Outside of misuse, the early design using a gasket in the hinge assembly (before new hinge sealant design) added a compounding factor that could cause more stress on the hinge than we intended. This process has since been redesigned to eliminate that issue, and all campers with the new sealant style (capillary dams and sealant above and below the hinge) will not be affected.

What is GFC going to do about it?

Because of the rare instance of this occurring due to what we consider improper usage, we are making some changes at GFC to define that usage. We realize that we need to document and inform customers of best practices to take care of their products. I shot a video yesterday informing the “instruction for use, care and feeding” that we will be releasing next week. This will go over what to do and what not to do so that there is a documented instance of these best practices.

Additionally, we are also working on a written manual for ownership that will further inform owners of usage, maintenance and troubleshooting. I can’t promise a delivery date on that information, but know that it is a priority.

We are still a small company that is figuring this out, but we always move quickly to resolve any issues that arise and make sure that they do not happen in the future. We do truly appreciate your guys’ feedback and know that we care A LOT about making sure you are stoked on the product. That was part of the reason for making this online community.

If you have any issues at all with a hinge, general concerns or really anything else, definitely shoot us an email at support@gfcengineering.com. We stand behind our product, and we are proud of the product we get to make for you guys and want you to be proud to own it and be a member of Team GFC.

And to clarify, the hinge is absolutely UV stable and is designed around a million cycle outdoor use case. You can learn more about it if you research “polyolefin living hinge”. It’s really a cool thing.

Please let me know if you need any clarification, always happy to answer questions like this.

-g

.

We have to feed them?? What do they like to eat? ![]()

Is the dog ventilation “hack” still an acceptable use case? It seems like that could be another scenario that would place additional stress on the hinge?

I am also curious if the dog ventilation should still be used? @GFC

Sorry for the delay guys, we have not seen a trend between using the dog ventilation and damage caused to the hinge.

How about mounting max tracks or a shovel/axe to the outside of the side door?

So, if UV/material isn’t an issue and I don’t “misuse” my GFC, it has to be an engineering issue right? What else is there? My driver side hinge broke first, complete snap with no warning. Now the rear is cracked both sides but barely holding on. And the passenger side still shows wear and is almost cracked. The repaired driver side is even showing stress in the same area that cracked. It’s got me to my wits end that I’m the 1%, and I haven’t “misused” my GFC at all, no donuts with the top open or anything like that.

I’d post all the photos but I’m a New User so I can only put one up -_-

If it makes you feel any worse I accidently drove about a mile at 65mph today with one side open and it didn’t break. Pulled a ratchet strap out of the passenger side panel and ended up using it on the driver’s side of the trailer and jumped back in without even thinking about it. What a moron.

I decided to take a look at my hinges today and did notice that each corner is slight raised compared to the middle section. My guess is that that gas struts are pushing the corners up and causing uneven forces during operation and constant pressure on the hinges in each corner while closed.

I’d check with GFC support, but if I saw a crack like that forming, the first thing I’d do is to drill a small hole at the trip of the crack to stop the propogation. The larger radius will dramatically drop the stress concentration at the tip.

There might be something to the idea that the force of the gas struts could be partly to blame. When open, I assume they are fully extended and the only load on the hinge at that point is gravitational. When closed though, they might be placing some load on the hinge right at the corner where your crack formed. Could CTE mismatch be an issue? I know those polyolefin hinges have a high CTE that is likely much larger than the aluminum door panel and the steel frame to which they are affixed. I need to check those number though. I know living hinge designs aren’t typically used under load

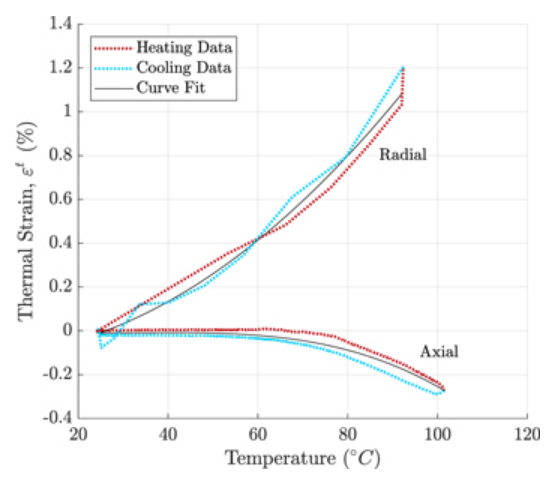

Ace7196: Glad there are some other nerds with trucks out there. On thinking about this more, it would be hard to really know what the actual thermal expansion in that hinge is and it might vary significantly from the bulk properties we get from something like Matweb. The high flow rate of the liquid polymer through the hinge mold during the injection process aligns the polymer chains perpendicular to the hinge direction. This is what gives the plastic hinges their typically quoted “million cycle” life. I found this course supplement from MIT’s Medical Device Design Course.

Anyway, the alignment of polymer chains can cause all kinds of weird stuff to happen to the thermal expansion numbers - even causing contraction on heating in one direction, while causing expansion in the other. The plot below is for drawn nylon 6,6 monofilament (fishing line), but I am using it to simply illustrate my point that weird stuff happens to thermal expansion when polymer chains get aligned.

https://iopscience.iop.org/article/10.1088/1361-665X/aad81d/meta

In short, I don’t really know enough about the thermal expansion to rule it out, but I do think that the constant force of the gas struts being reacted by the polymer hinge seems like a bigger issue, especially give then their viscoelastic nature. (GFC folks, please don’t take this as design criticism. Just a conversation!) I’d be interested in hearing the GFC perspective on the design and gas strut load path when the panels are closed. I haven’t looked at the latching up close (since Overland Expo West), but is there a load path for the gas strut force when the panel is closed that bypasses the hinge. or is that force reacted by the hinge itself? Could a set of links be used in place of the the gas strut that would induce no force on the hinge when closed? I don’t mind lifting the panels into place. A 1% failure rate seems pretty good, but that is only in the first few years of the camper life. My order number is nearly 800 range, so about 8 other people will be dealing with this by the time I get mine. If it is a loading issue, then I suspect that 1% number might jump up as more of these hinged age.

How about something like this as a fix? Have to line up the pivot point better. Mount the hinge to the extrusion with T nuts. Through bolt to the door. Shim to fit. Paint/anodize to match. Maybe three per door. Leave the living hinge in place for waterproofing, alignment… GFC could CAD design the hinge and maybe produce it with robots.

I wonder if would be possible to move the mount point of the struts. This would change the pressure to downward when closed, something like the picture below. When closed I think the latches would take the brunt of the downward pressure. I think you would have to have the perfect length strut or one that puts zero pressure at the end of the stroke, otherwise when wide open the strut might be forcing the hinge outward.

Does anyone know how many gfc owners have had damage to their hinges? If its 1% that means it’s 3 out of 294. As of today.

1% seems low, but is really not great in the consumer products rhelm. GFCs are awesome and I really want the design to continue to improve. That is part of what is great about this forum. Gives users a direct way to provide feedback. Smart on their part for setting it up.

Once again, I think that moving away from gas struts would be great. A 4-bar linkage (panel and frame would be two of them) with two bars replacing the gas strut would be strong and a “never needs fixing” solution. Hard stops would hold the two bars collinearly when the panel was open, forming the same kind of triangle that the strut, panel, and frame create now.

Strength: Living hinges are very limited in their ability to bear loads (whether it be tensile or compressive stress or shear strain). This is one of the major limitations with living hinges.

Source: Everything You Need To Know About Living Hinges (Design, Prototypes, and Manufacturing)

I feel the actual hinge is worthy of holding things together for the paneling, but I don’t think it can handle that upper strain pushung away or out. It might be worthwhile to do what was suggested earlier it the thread, adding on some load bearing hinges to help mitigate the stressor.

I’m no engineer, but I think redundant load bearing would help reduce failure rates even lower than 1%.

That being said, I trust gfc completely with their product. This whole conversation is just interesting. I’m unit #413 so I should be done by end of October at the latest. I’m curious to see and feel how these gas struts apply force when opened and closed. I have a feeling the solution will be far easier than we think, and likely an easy self install. It doesn’t loom like the source of the stress fractures would be hard to locate and reinforce. These hinges are incredibly strong, I think it’s just a small area that triggers the whole failure.

That solid bronze hinge came off of an old wooden sailboat.

I bet some more discreet hinges could be designed that would look good. I do like having the 6" long straps to support the entire weight of the door. I think that having the present hinges left in place would keep the alignment set and the new hinges could be tweaked to fit perfectly.

This solution could be owner installed and the extrusion/frame sealing wouldn’t have to be disturbed. GFC could just send them out to the present owners and be done it.

A fix that requires removal of the living hinge would also have to deal with a water proofing gasket.

I wonder in 2- 3 years if there will be many more failures? The ones that have failed are the early ones with some miles on them. Personally, I’m most worried if one fails on the highway at say 70 mph. It could do damage to your truck or someone behind you. Once that wind catches behind the door, it would probably thrash around and then tear off. I might connect some sort of safety strap on the inside so that it wouldn’t become disconnected from the frame.

Is this the type of bar you are talking about?