What I’m thinking about is not a full length hinge but a half strap hinge that would attach to the extrusion with T nuts and bolted to the door. The plastic hinge would be left in place to provide a water barrier. Ideally you would install this prior to hinge failure so that it would assure proper alignment. Two or three per door. They would be painted to blend in with the extrusion and door. The hinges would span the gap and be shimmed if necessary. Also a plate could be mounted on the extrusion to facilitate the fitting of the strap hinges if the holes don’t line up. If you could find a similar hinge without the holes then the fitting might be easier. Maybe GFC could fabricate a custom hinge and mass produce it with their robots.

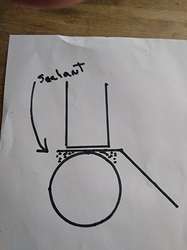

Perhaps something like this.

Yeah I get the concept. If I were going to design something like that I would machine a couple of smallish ones for the end of each door. You could make something small and sexy and it would help take the pressure off the plastic hinge.

But, I was looking for a hurricane type hinge that is just a 180 deg hinge. Seems like someone should make one. GFC could design one as well if needed. It would just be 2 extrusions male and female.

GFC is shipping me a rear hinge. If mine fails completely I’ll have one to replace it.

A hurricane type full length hinge would have be sandwiched between the extrusion and the frame. IMO the essential problem with this is that mating the hinge between a tube and the flat extrusion surface is problematic. That’s why GFC is using the sealant to fill in the gap.

Understood. But it wouldn’t be plastic and some lateral pressure would be acceptable.

They could also switch to a square upper tube. That has it’s challenges as well but should be doable for new construction.

Heck, if they made their own hinges they could make the one side curved so it fit right on the tube!

or come up with a hard plastic or aluminum/steel spacer that is curved on one side and flat on the other…

then use a rubber gasket on the tube vs spacer side to help seal at the small imperfections at the welds…

Looks like something from the original concept that included a soft side that never made it to production. Could just convert to soft sides (I’d consider if I lived in SoCal).

Build 45 here. Mine has been trouble free so far. Debating having it refurbished because I’m not too crazy about the glue. Do you guys at GFC think the failure of hinges is inevitable for the early adopters? If so is there a limited timeline to get the rework done? I don’t want to miss this if that’s the case.

@NYCO Good idea but I think it adds complexity.

@ace7196 - Yes! We’re going the same place with our ideas. I hadn’t thought about using the extrusion but that’s an interesting thought.

I really don’t see why nobody has made (or at least I couldn’t find) a hurricane type hinge that would fit. I find the idea of using the lower track for the female piece of the hinge intriguing…

Now that my hinges are failing - I’m not so excited about the idea of plastic hinges.

I’m skeptical that the plastic hinges will hold up over the long term say 5 years from now. Sure they can tolerate a million or whatever cycles in the confines of a testing lab but that is far different than all the environmental abuse they’ll be subject to on the road. The bending part is only about a mm thick and the installation isn’t optimal. You would think that some of the big canopy and camper manufactures would be using these hinges if they were up to the job.

@rajacat I called Monroe Engineering this morning. They are a manufacturer of these hinges. I don’t think GFC buys directly from them, but might buy from a subretailer or similar company. Anyway, the guy I spoke with said they don’t do their own testing, but had a third party do a life test out to 1M cycles. He said that they originally designed the plastic hinges for the aerodynamic fairings on the back side of big rigs (see image below), which see pretty decent wind loading and lots of UV exposure. He was really confidents in saying that they haven’t had any issues with cracking or failure when I asked him about it. This lends some more credence to the idea that the original failures really were a manufacturing defect at GFC and not a more fundamental problem with living hinges in general.

@MechEMike I don’t think that application is under the same kinds of loads the hinges are experiencing in the GFC application. Also, though they may be under load, they may not be subject to the same number of cycles as in the GFC application. The testing likely also had specific criteria regarding the manner in which the hinges were mounted.

In the GFC application the hinge is both under load at all times and likely cycled regularly.

Anyway, I agree, it was likely an assembly issue. I think adhering the hinge to the aluminum extrusion such that it’s supported along its length and flat will greatly increase the life expectancy of the hinges, as long as all that criteria is met. Unfortunately, it just makes a possible failure more of a mission to address.

@Pilosopo Yeah. I didn’t mean to say that the conversation with Monroe puts this issue to bed. It is just another data point to give us some confidence.

@MechEMike And I didn’t mean to imply that’s what you were stating. I appreciate the discussion

I think the biggest issue was made clear to me when my passenger side hinge failed.

When the panels are closed, the hinge at 90* (ish) the struts place a constant, upward pressure on the assembly. I don’t think the hinges were ever designed to be subjected to that load in particular. A tension load for sure, but that load is inherently difficult to manage as it’s not consistent along the hinge length and comes close to being like shear, which living hinges are not ideal for (I consider the hinges to be similar to living hinges)

If when the panels are close the system went over center for example, such that the loads were closer to zero or in tension pulling on the hinge, I think the hinges would last longer.

Meanwhile while we debate amongst ourselves gfc has a whole bunch of people with broken hinges still needing a retrofit and reseal and still waiting for an announcement on the repair program.

An announcement that there will be an announcement about repairs got the angry villagers to put away pitch forks only temporarily.

There has still been no mass communication about the potential safety issue at worst, or potential inconvenience at best. If it was announced, I haven’t seen it.

I was reminded how awesome the gfc could be last weekend. I pulled up to camp in the dark, popped open the top, threw a sleeping bag and pillow upstairs and went to sleep. At some point in the night I woke up to rain hitting the roof. Went back to sleep since the tent is nice and dry. Woke up again to a great sunrise, closed camp in 2 minutes and drove off to explore.

I was also reminded how much the broken hinge issue sucks. Every time I had to get something out of the truck bed I cringed. I am too afraid to open my side hinges. One is original and one is a replacement for the complete failure I experienced. My rear hinge looks like crap too even though it is a replacement because of the welds and no spacer. See pictures in one of my posts above.

I bought this thing partially for easy side access to the front of the truck bed. Not having that access sucks.

Inevitably I was asked what is on my truck and if I liked it by a couple different people. My answer remains “I liked it until the doors fell off.”

I’m in the same boat. I get asked about it ALL THE TIME. My reply is - ‘yeah I love it - talk to me again when I can open the doors and I’ll show it to you’.

Mike is making all the right noises - but I’m still keeping one door shut and PRAYING the rear door doesn’t explode (couple inch split on one side).

They are sending me a replacement rear hinge in case it does… fingers crossed. I hope it doesn’t explode on a ski trip when it’s 10 below, I have the family, and the dog is back there.

About that mobile repair announcement after Thanksgiving, it is another week past Thanksgiving. No announcement yet?

By my calculations, they have another 49 weeks til Thanksgiving.