Hi all,

@mattyd, I’m sorry about your hinge. We’ve received your email and I will call you in a few minutes with the next steps.

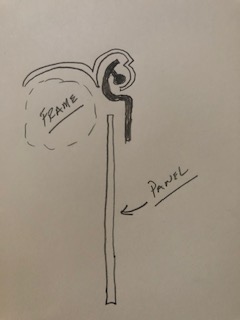

For everyone concerned, there is a small group of sealed campers that were assembled with the crown molding that can impede the hinges ability to lay flat. I’m happy to explain why.

Basically, these campers were assembled with the crown seal, and waiting on fulfillment, when production started using a liquid sealant to further water proof the camper. The production team retroactively sealed them in order to provide the most protection against water intrusion. At this time, hinge failures were only starting to crop up, and we hadn’t yet pinned down that the crown seal was what was causing these hinge weaknesses.

Since this revelation, crown seals have been fully eliminated from production. All resealed campers have their crown seal removed prior to installing new hinges and sealant. This method has proven itself as a strong permanent solution, as the hinges are able to lay flat and perform without issues.

@ETALATE, I’m sending you an email today to get some more details from you re: your holes not lining up.

@TReitz your camper is well outside of the zone of potentially affected builds. Yours was assembled with the latest practices, and I am confident in its performance. I wouldn’t recommend removing your struts.

We’re working on getting @Mike_GFCUSA back on the road to get all of these campers fixed up for good. We will be resuming the PIT on August 1. We would like to resume sooner, but we used up all of Mike’s PIT supplies for production campers after the pandemic shut down while we were waiting for our suppliers to resume fulfillment. Our suppliers are back up and running, and taking into consideration the lead times associated with these supplies, we determined August 1 as a good date to resume the PIT. Of course, if we are able to resume the PIT sooner than August 1 we will.

@Mike_GFCUSA will be reaching out in the next few weeks to reschedule everyone’s PIT stops.

Thank you guys for your patience. I really appreciate the opportunity to provide this information for y’all.