Hey y’all. Sorry if I missed this somewhere but does anyone know the exact width of the beef bars? I am picking my unit up in January and wanted to get a jumpstart and make my own set from 80/20. So I just need a width of V2 standard. Thanks

The standard beef bars would be 53” to match the width of the tent. That’s not including the brackets on the ends.

Thanks!! This helps a lot

You can also check out our website’s accessories page where you can view the beef rack cross bars and all the specs.

- Standard Bars (53")

- XL Bars (59")

Hit us up if you have any additional questions.

Tnutz is offering a 54” prinsu kit for black bars. Just tell them in the comments you want 53” instead. They fit perfectly on my standard V2.

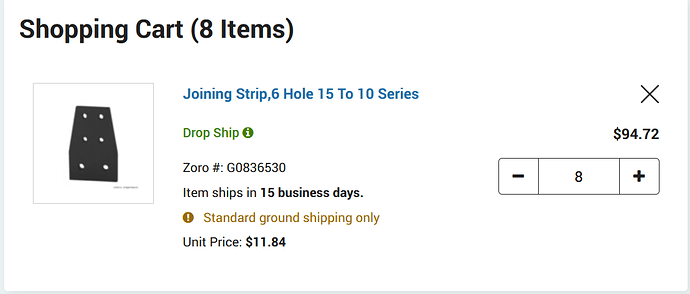

I used Zoro for the tower brackets, but beware shipping is slow right now: 80/20 Inc 4519-BLACK $11.84 Joining Strip, 6 Hole 15 To 10 Series | Zoro.com

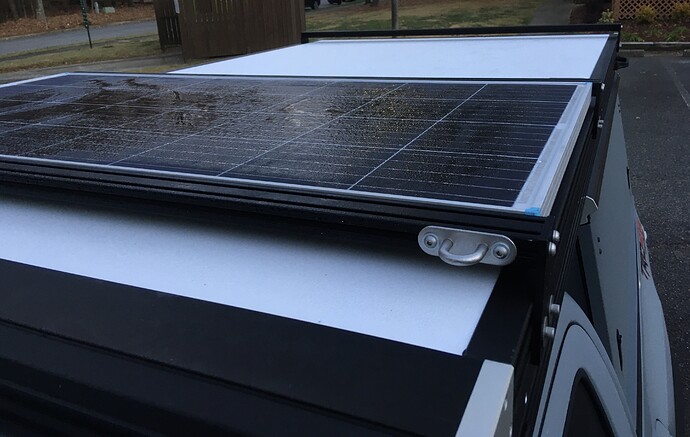

Nice!! Thanks for the pics. I picked up 3 sets of bars with all the hardware and brackets for $160 shipped. Pretty stoked on this. Is that a solar panel you have happening in the first photo?

Very good. Don’t forget to grab some track nuts (Gzila: GZila Designs | 1/4-20 Track Nut for Go Fast Camper | Order Now!) and washers. I had to drill out the mounting holes in the brackets for track nuts (base width of nuts is 1/2”)- but beware, you only need to go about half way in, not all the way through. Use a little drill oil (or canola oil) and this will take you a few seconds per hole with firm pressure on a hand drill.

Yes, solar is Renogy 175 watt rigid panel. Amazon has sales on these every now and then ($180). Had an incident with a flexible panel on a van a while back, even with 3M UHB tape and RV seal tape, with enough time, heat, and wind, those things can become kites on the highway.

Yea I picked some of those up as well. Thanks for the tips. I myself don’t trust the adhesive and also want a mechanical connection with the bars and panels. Especially being in the PNW with lots of rain and weather. Those loop attachments you have look handy on the front of those bars.

Yeah, normally I would loop straps around the bars but with the solar panel taking up that space, these make it much easier.

Stainless steel padeye loops:

Definitely man. Nice set up! Picking up my V2 next month. Couldn’t be more pumped. I do a lot of sewing as well so probably gunna take a shot making these fitted sheets in different patterns. Working on my design now for the build out. Thanks for the info!

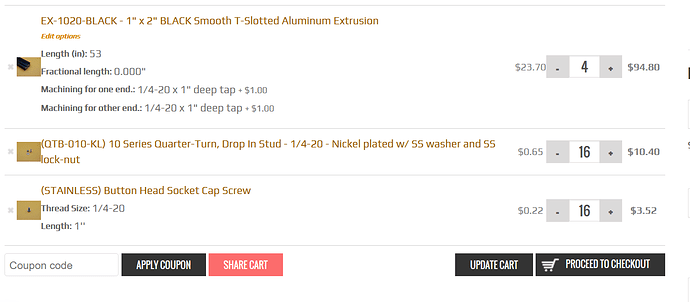

Hey Taq, I am looking to copy your cross bar build for my future V2 (I am picking it up in March) and wanted to make sure I wasn’t missing something on the cross bars. Below is what I am looking at purchasing and want to make sure I am not missing something or ordering incompatible pieces. I am going to install 4 cross bars, which is probably overkill, but I would prefer to have an extra instead of having to pay for shipping if I decide I want another one. I have never worked with these extrusions before so this is all new to me.

Did you use any loctite on the side mount bolts? Everything holding up well for you so far with these?

Yes, it looks correct.

The 3 essential pieces are, per bar:

- One EX-1020-Black 1"x2" smooth T-slotted aluminum extrusion (53")

- Two Joining strips (15 to 10 series, 6-hole)

- Four 1/4 - 20 GZila Designs track nuts

The nice extras are:

drop in studs/washers/lock nuts

padeyes and t-nuts

additional 80/20 specific hardware (cable ties?)

Also, I recently found black 1/4" washers at Lowe’s that look much nicer on the black supports.

I haven’t used threadlock on these, yet, and with about 5k miles and lots of freezing-thawing, there aren’t any indications of loosening. There are lock nuts that come with the bars, so that helps. My experience with aluminum is that a little seasoning will probably seize the hardware together naturally but I’m keeping my eye on it without losing any sleep

Just got all my pieces from Tnutz, Gzila and 80/20. Total for everything was not bad. Think it was around $180 for 3 T bars, 6 brackets and T nuts. The one thing you’ll have to do is use a flat bottomed metal bit so the t nuts sit flush in the brackets. At least with the pieces I got.

I used a standard 1/2” metal drill bit. You don’t need to drill as far into the metal as you might initially think. Test a track nut for depth periodically as you drill (widen) your first hole and you’ll see what I mean.

Yeah, I agree the black washers would probably look better. I was actually thinking about maybe using black nylon washers to cut down on potential vibrations, but I am probably overthinking it and will just go with something like what you suggested.

I appreciate it. Thanks for the information in this thread.

Has anyone used the diy bars to haul anything that weighs over 150lbs? Have to deliver a massive kayak about 600 miles in a month or so and was wondering if I should just go DIY or buy the actual Beef Racks

I’ve hauled several pounds of lumber on mine. No issues

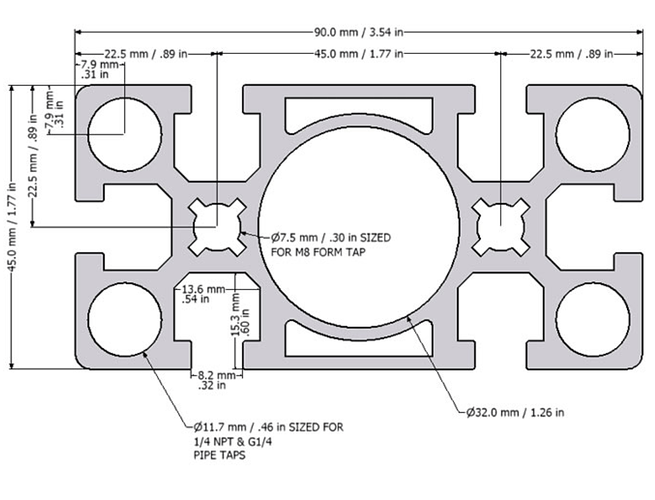

I can get super strong 1.77" x 3.54" aluminum extrusion with the added strength of a round core and can get cut precisely to 53". Same two T-slots top and bottom as well as the sides. Can accept up to a M8 bolt using positioning nuts that can be inserted at any time when the rack is in place. Only comes in silver anodized but it is beautiful…would look great with black towers. Check out what we have built with this stuff: www.Van-Mod.net.

I’ve got a Revel too and have seen your products over on one of the FB groups. You do beautiful work! I didn’t realize that the extension t-slots were the same as GFC. Where do we source your t-nuts from?

Keith