Well, I finally have a weekend to reset and I took an extra easy day to start it all off. Who would’ve thought working IT in wildfire would be so busy  . Plan A was to take one kid this weekend, but I knew that wasn’t going to be a thing. Packed both boys into the rig and rallied out to my favorite area.

. Plan A was to take one kid this weekend, but I knew that wasn’t going to be a thing. Packed both boys into the rig and rallied out to my favorite area.

Had to stop in the little community of Likely for a few hours to talk business which brought the boys and I to the rec site quite late.

I needed to get the kids settled, so I fired everything out of the truck shotgun style and put on some Looney Toons DVD. I had to work the next morning so I quickly set up the Starlink.

This is when I was reminded of the fact that these units can take an extremely long time to update. Especially when you’re in the confines of BC’s beautiful rec sites. I got it working well enough to check in figuring that would do the trick.

This was my original evening setup which changed multiple times. I got it working well enough to try and sign in to work. No dice, no stable connection in this location. Then I had to take a side bar on the starlink to deal with the first challenge of the day. Cooking breakfast in the rain with two kids, while you’re trying to work.

Once I was done that, I came in to a suspicious amount of water splashed in the front right corner. Now, as a father, you’d expect my first instinct would be to question the children. Which I did, and since they’re still learning the difference between the truth. I can never really trust them. As I investigated further I noticed water making it’s way down the underside of the sleeping platform to the extrusion and dripping.

I placed the cup there in the meantime as I searched out the culprit. At this point it is raining heavily and the children are up top eating eggs, bacon and watching looney toons. I investigated the changes I have made that have since resulted in this. Where’s Dishy?

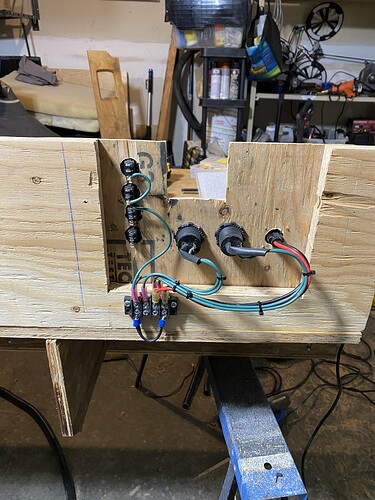

During the breakfast prep, I opted to move the starlink onto the roof. Tried various things like just putting it on the roof. It DOES NOT like to not be level. Then I figured…why not take the shovel off and test the two ‘qwik fists’ i have and mount it in the extrusion. So that’s what I did.

While doing that I came back in and it dawned on me. The truck isn’t level, that’s why it’s leaking. When I was up on the ladder fiddling with the starlink. I noticed that during heavy rain the way the camper is it just can’t shed the water quick enough. So a little makes it’s way along the edge. Well, this neat thing called gravity showed me that it’s flowing towards the back.

Water intrusion issue solved!!!

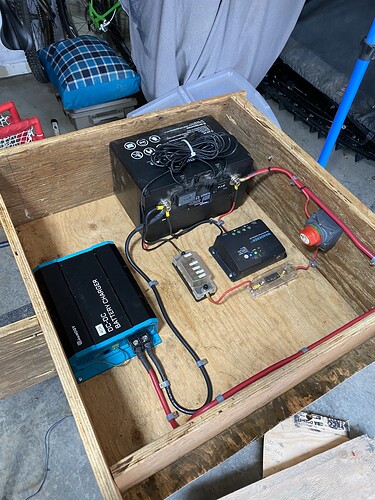

Now, during all this the Starlink is doing its thing. I didn’t take a shot of the usage overnight, but I was down so I started the truck and turned on the dC to DC charger.

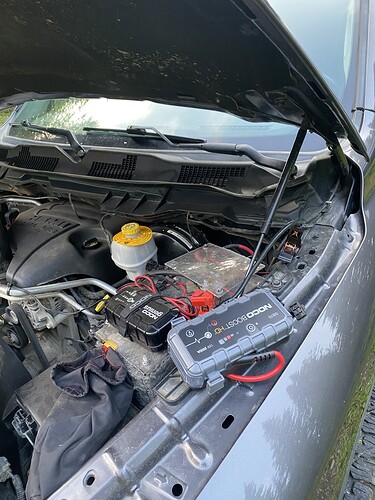

I let it run for a bit while I tried to work. Then I thought I would try the DC to DC charger without the truck running. I had a thought that it should not deplete the truck battery because it surely must have some form of protection. It did not.

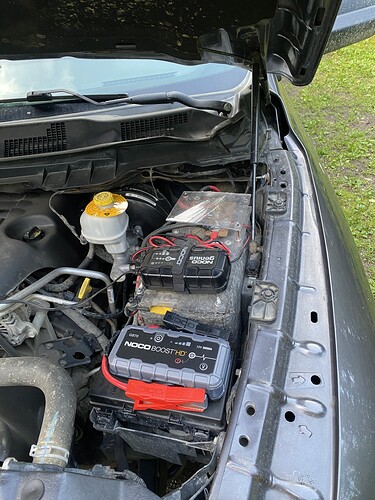

Luckily, I knew I had the NOCO Boost on hand. So hooked that up and flashed the rig back up. Then I thought ‘Hmmm, I wonder if I should mount this here?’ Thoughts?

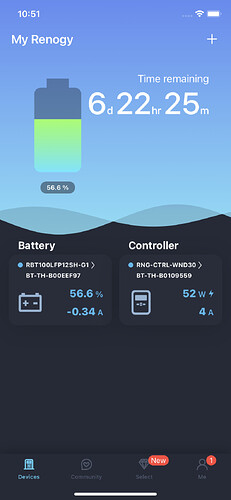

As you can see I’m not getting much work done, but that’s ok, the starlink isn’t providing a consistent enough connection yet to connect to the VPN. But, it did finally give me stable enough internet to work from 10am to 4pm. Here’s where I was at power wise at the end of the day with a laptop and the

You can see, the two while trying to work consume quite a bit of juice. 100W solar isn’t gonna keep you steady in Central BC that’s for sure. Not unless you have no trees  .

.

So as you can see it takes about 52W. I figure when it’s time to upgrade the solar I will go with one big 400W solar panel.

With the work day done it was time to entertain the kiddos. Off fishing we went!