Now that you bring that up I did the same thing. Couldn’t remember if it was Will or Kris that I spoke with. Now I do remember it was Kris

Thanks again for the heads up. He was an awesome dude and was pretty funny to hear him talk about the forum. You’ve given him an alter ego of sorts that he seems to be embracing lol. Have a great weekend.

Hey bud…sorry to keep harassing you about your ladder but I just got mine in the mail with the hardware and its sick! One question I had is do the GFC T nuts come with the washer to mount the hardware or did you buy those? If so, what size? And what do you mean going with the “smaller tnuts”? I thought they were just one size.

Thanks again

Do you have a link to the mounting hardware? I’m going to order a ladder as well and really don’t want to call and bug them. TIA

I messaged them on IG and they said to call Vegas shop. They were only ones with them and the brackets weren’t on their site. I plan on calling later today. It’s business for them, wouldn’t see it as bugging them.

Yah its not on the website and definitely not bugging them. Kris was stoked that I called and was awesome to do business with. I got my ladder yesterday and I am incredibly happy with it. Super easy and comfy on the bare feet

Just reached out to CVT in vegas and spoke to JD. Looks like they’ve been getting a ton of orders. Thanks, @crazyfingers!

Yeah just ordered mine today lol.

Your not bugging me at all and sorry for the late reply. The track nuts come in two different sizes they come in 10-32

and 1/4-20. The holes on the mount are a little bigger then the track nuts so you will need 4 washers as well. I don’t remember if the CVT mount came with any or not.

Might be a dumb question but which is bigger, 1/4 20 or 10-32

Ordered what I thought was 16 1/4-20 from gzilla but trying to install a custom 8020 rack with bracket and there is too much play by far

I just went through this too, also on an 80/20 custom rack.

1/4-20 is a larger diameter. And the 1/4-20 tnuts are also deeper (more thread depth so they can carry a larger load) but as a result they stand out beyond the face of the extrusion. And that’s why you can’t get your bracket tight.

You need to take up the space between your bracket and the face of the extrusion that the tnut creates. The two options I’m aware of are:

- you add a washer that has a big enough inner diameter that the tnut fits inside it and is deep enough that the tnut is no longer sticking out past it (this isn’t a great description…tell me if that doesn’t make sense and I’ll take a photo tomorrow) or

- you mill/drill into your bracket so that the part of the tnut that sticks out is embedded in the bracket enough that the bracket can be pulled tight against the extrusion surface. (Kind of like what GFC does with their beef bars).

Makes sense but crazy that is the solution. I just ordered some 10-32 in the hopes this will solve the problem but it sounds like it will not.

From what I can see the action of the bolt going through the nut and pushing against the back is what tightens the tnut to the edges of the extrusion.

If that is true I might be able to get a similar threaded piece at the back to stack on it and cause it to press sooner…if that makes sense?

I definitely would be curious what washers you used as it may save me some drilling

Seems I have to do some drilling anyway since the hole distance is 7/8 and not 1"

Looks like I’ll be running into this in the near future.

Judging by @mode7’s pictures, maybe the 10-32 allowed for flush mounting?

The 10-32 tnut is flush with the extrusion.

If whatever you are attaching is thin be careful the bolt doesn’t bottom out on the extrusion as it will scratch and dig into the aluminum. Anything over 1/8” ish should be fine.

10-32 will solve your problem. It sits within the extrusion so your bracket will be pulled against the extrusion instead of the face of the tnut. You’ll have to decide if 10-32 is strong enough for your application

I’m not sure I’m following your idea about a threaded piece at the back. I might need a sketch.

I’ll post some photos of washers and drilled out brackets tomorrow.

@Rising, here are a few photos as promised. I know the depth of this 1/4-20 tnut surprised me too so hopefully these will help others who are trying to design their own mounts and brackets.

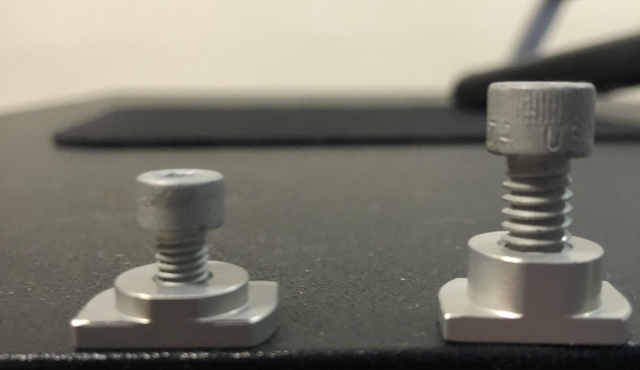

This is 10-32. Because it sits fully within the extrusion, it tightens your item to the extrusion “as expected”.

This is a 1/4-20 with the nylon washer. The washer has a 1/2" ID and is 1/8" thick so it covers up the part of the 1/4-20 tnut that sits beyond the extrusion. That is clearer in the second photo. You can find similar washers on Amazon or at your local hardware store in a variety of materials (nylon, rubber, steel, probably aluminum too).

And finally, if you don’t want to use a washer with the 1/4-20 tnut you can either drill through or mill out your bracket so that the tnut is inset within it. My brackets are 1/8" aluminum so I had to drill all the way through like this:

Excellent write-up and photos. This helps immensely.

Is this the washer?

Nylon 6/6 Flat Washer, Plain Finish, Off-White, 7/16" Hole Size, 0.5" ID, 0.69" OD, 0.03" Nominal Thickness (Pack of 100) https://www.amazon.com/dp/B009OLQWLC/ref=cm_sw_r_cp_api_glt_fabc_H307QC3WD13BNWAR2Y02?psc=1

@bigskydu, 0.5ID is right but I’m having trouble getting that source to give a thickness greater than 0.03"…which is not enough to rise above the 1/4-20 tnut. I suspect they are out there on Amazon but I found mine at the local hardware store.

Eek, I misread the thickness as .3, not .03. Thank you.

These seem like a reasonable option that might also help protect the materials as the nylon does: https://www.bridgefasteners.com/products/1-2-neoprene-316-marine-grade-rubber-bonded-sealing-washers-316-stainless-steel-quantity-25-by-bridge-fasteners?_pos=7&_sid=b7705bf6e&_ss=r