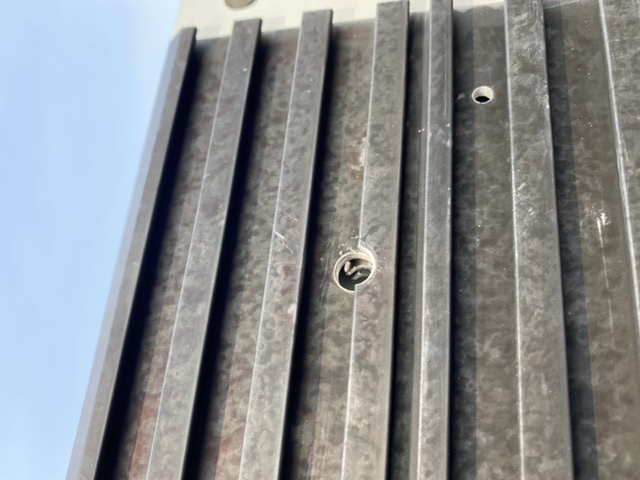

Yeah there is raw aluminum attached to the holes in the inside of the rails. From when they drilled the holes.

If it makes you feel better, those panel hinges look pretty swanky to some of us.

RUST!!! This is the first I’ve heard of that other then inside of the tubes of the space frame which I believe they fixed. Can you take a pic of it?

Nope, I fixed it quite awhile ago. It was rust inside the tubing that contains the main latch pins for the tent, which prompted the redesigned, extruded aluminum parts for the front & rear.

Over time, water would leak in through the ends or the small slots for the pin levers, and the inside of the steel tubing would rust. I disassembled it, cleaned out the rust, hosed the interior down with a rust inhibitor, and it’s been fine. I’ll have the aluminum parts installed when the hinges are replaced.

well they used water as part of the curing for the sealant - not sure they still use that sealant - so water inside the frame was a thing at least. my front tube of the frame (lower) was rusty, i had to buy and spray stuff in there. reminds me i need to check that again

@Toyoyotaco something doesn’t add up. Show a picture of your truck and the GFC.

Some companies charge extra for an appearance like that. Think about those “distressed” blue jeans.

This is kind of concerning. As much as it sucks for @Toyoyotaco I do hope this is just a QC issue and not a change in material to speed up production.

I doubt GFC is changing the perimeter frame extrusion - what he has is what they’ve all had from the start. Last I knew, they had brought their coating work in-house, and seem to be happy with the process that’s been in place for some time.

From the condition of the holes (not deburred, and no paint), it looks like a one-off production issue. I hope they haven’t changed their coating process, because the stuff they’ve been using has held up very well for pretty much everyone. It’s hard to say from the photos, but that frame doesn’t look like it was ever prepped for a coating, and was assembled out of sequence.

I Also hope this is not a fast track for the production process!!!

Maybe another GFC owner around build #858 can post some photos to compare the extrusion.

They have changed to anodizing the extrusion

I think @Toyoyotaco hit it. It looks like Anodizing vs powder coating.

Anodizing is probably a good idea. It does look a little weird on this one…

@artieTwelve - I saw you mentioned your unit is 850. Do your side rails look Toyoyotaco’s?

I’ll be picking up #859 next Wednesday. Will be interested to see what the anodizing on mine looks like.

@GFC_Taylor @Mike_GFCUSA

Can you guys shed some light on this or has something changed again in the production line?

Hey all,

@Toyoyotaco brought his camper back to us on his way home from Billings so we could check it out. We were able to do a little detective work to get to why his extrusion looked like it does in these pictures, and clean his camper up for him with just some soapy water and a green scotch-brite pad.

First, an update:

We’re anodizing our utility tracks now. This is a huge upgrade. Anodizing hardens aluminum leading to a more durable surface and a finish that we’re really stoked about. With regards to speed, switching from powder to ano doesn’t actually save us any time. Considering this is your utility track, and it’s going to get a lot of use, durability is key. Anodizing also takes up less tolerances than powder coating, leading to better fitment during assembly. In the end, we’re always innovating, and we think the anodized utility tracks are all around a step up from powder coat.

So what happened?

Jose saw some smudges and spots on his extrusion that wouldn’t come off when he wiped them with a cloth, so naturally he took his truck through a touch free car wash. This led to the small splotches of discoloration throughout the utility rails that you can see in his photos. Why? Anodized aluminum is hard, like glass hard, and like glass, residue from oily detergents and waxes can leave streaks and marks.

How did we fix it?

The best way to clean anodized aluminum is with a few drops of soap in water, a green scotch-brite pad, and a little elbow grease. This would have taken the initial smudges off and definitely removed the discoloration caused by the car wash.

In conclusion, I’ll do some digging/experimenting in order to recommend the best cleaning practices for campers with anodized utility rails. For now, the best option is hand wash with good ol’ soapy water. I recommend doing this with a beer in hand, cut off jeans, and some very loud ZZ Top. As always, I appreciate everyone’s feedback here (especially @Toyoyotaco’s). Y’all are the best customers and always help us figure out ways to make the GFC experience better and better!

Honestly, I wish mine were anodized vs powder coated. Definitely an upgrade IMHO.