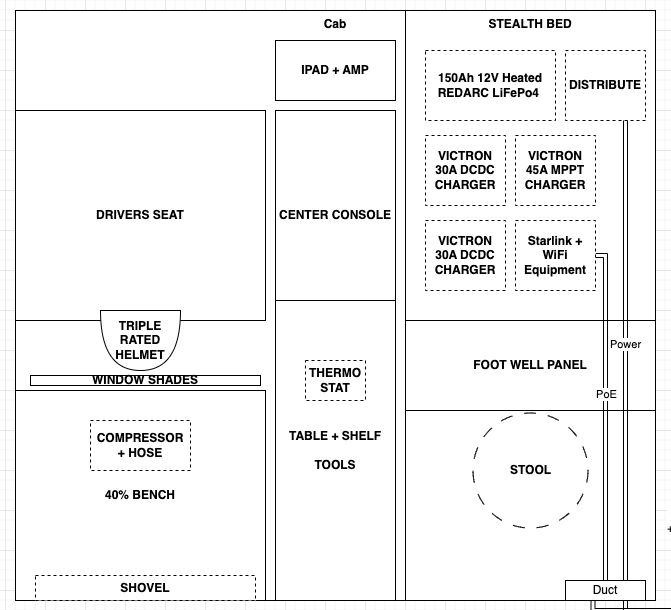

Cab Design

Here’s the current design for the cab. I’ll break it down below, but first - let’s talk weight

Weight

It is well-known that almost all overlanding rigs based on the Tacoma are overweight. I already said in my first post that keeping under GVW is a top priority for me. Before I started designing anything, I weighed my truck. As I am designing and changing things, I am maintaining a spreadsheet with all the current additions and removals. Everything in my vehicle has to be optimized for weight to achieve my goal of keeping under GVW. The GFC is a good base because it is so light.

Seats and bed

I ditched all of the back seats in MK1. I don’t have a passenger very often - maybe once a month, and there is always a way around it. It’s a convenient fact that most people don’t think taking out their passenger seat is normal. If everyone took out their front seat, chaos would probably ensue, and how would anyone ever ride shotgun? My approach is more pragmatic - I have already removed my passenger seat, and when I am back in Utah next I will re-install the 40% bench seat. Now if I take a lady on a date, she can sit behind me and give me a back massage! Only upsides here.

In all seriousness, removing the 60% bench and the passenger seat open up a world of possibilities. Without this, sleeping comfortably in a DCSB Tacoma without popping the tent is not possible. As much as I love the orange color, it does attract a lot of attention when you pop the tent.

In this configuration, all of the passenger side of the vehicle can be turned into a bed, about 10" off the floor pan, and if I remove the glove compartment and the passenger side knee airbag, I have about 7 feet to stretch out.

Removing the unneeded passenger side seats probably saves me 100lbs.

Desk

The cab is better than the tent as a workstation when it is nasty out. I am an embedded engineer, so work often involves working with instruments that I’d rather not have exposed to the worst of the elements.

I plan to design a temporary desk that can go over the area between the center console and the door. A more permanent desk will occupy the space behind the center console.

When sitting at the desk, I will remove a part of the bed to allow my feet to rest on the floor pan.

Electrical System

The cab has turned into my workstation, and most of my larger electrical loads are located here too, so it seems like a good place to put the electronics.

When it comes to electronics, I used to cheap out and get Renogy parts, but I was always annoyed by the cheap build quality and the lack of solid documentation on communication protocols - I want to be able to interface everything in the system with a controller that I build myself - more on that later.

Chargers

For this build, I’m choosing Victron chargers. They seem to have the best documentation on communication protocols in the market. Two 30A DCDC chargers plus an MPPT charger get me fast charging when my engine is running, plus full utilization of my solar array.

Batteries

Based on my power budget, 100Ah is the least I could possibly get away with, but I would have to keep the bank 100% charged at sunset to make it through the coldest, longest winter nights.

I am planning to use a REDARC Alpha150 battery. This thing is a beast. I was considering two 100Ah self-heating Battle Born batteries, but I was won over by the extreme power-to-weight density and the open communication protocols of the battery. The solution went from 2 batteries weighing 31lbs each to 1 battery weighing 34lbs.

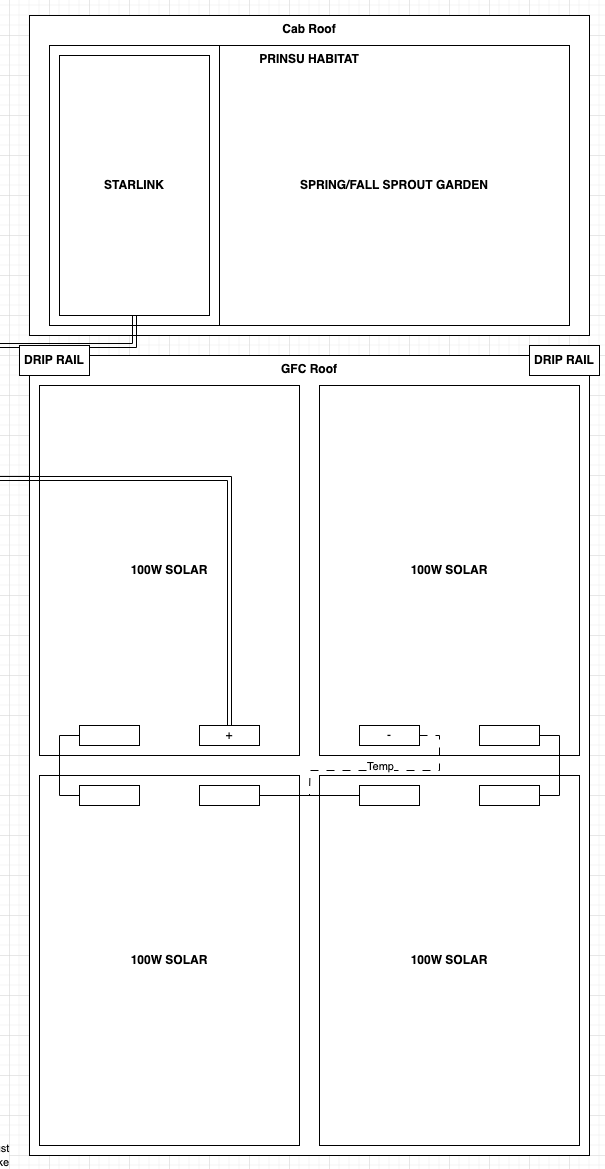

Starlink

I’m sticking with the Starlink system, but converting it to 12V using Dishy Dualie - I’ve pre-ordered this and it should be here in late October. I’ll pair it with a Ubiquiti Unifi router since the Dishy Dualie has a PoE injector for the router too.

HomeKit

I’m an Apple customer through and through - so I will have a HomePod mini in the truck to interface with HomeKit accessories. I’m planning to use a bridge from HomeKit to my camper’s CAN bus to control switches and read temperatures and tank levels.

Distribution Panel

Bus bars with fuses is all this is. My electrical loads will all be controlled over CAN bus, so I should only need to make +12V and CAN connections since all the grounds can be referenced to the chassis. This is what CAN bus was designed for, after all - reducing the amount of copper. Copper == weight

Ducting

Okay, let’s jump to the back of the cab and talk about this duct box. On the back wall of the tacoma cab there are two rectangular vents that vent to the bed. These are there to make your AC system work, but I am going to hijack one of them to use as a passthrough into the cab. I am going to run heat and power through this opening. Heating is something I’ll talk about later, but it is coming from the bed, through the rear fenders.

Hint: the thermostat box is part of the heating system

iPad + Amp

This is a dream project and probably won’t happen until later, but here’s the idea - ditch the factory stereo for an iPad Air or iPad mini, and design an interface board that connects the iPad USB to an Amplifier, the steering wheel controls, and the backup plus front-facing cameras. I’m confident that you could do all of this from a microcontroller, but this is a low-priority project compared to everything else since that system already works.

I removed the DCM Telematics module since I don’t use the remote start feature or microphone and don’t like Toyota spying on me, and it is on my to-do list to bridge the right side speakers so I can listen to the right channel of my music again.

Other

Triple rated helmet - I was rolling around with 3 helmets onboard my MK1 camper - climb, backcountry ski, MTB. There are now many companies making helmets that do all three of these in one. I will be picking one up this winter.

Window shades - for sleeping and keeping things cool

Shovel - this is my recovery system. This is an overlanding vehicle. I don’t intend to get into situations that are serious enough to require a winch, and 100lbs extra on my weight budget for the lightest bumper + winch combo seems like a huge sacrifice. I don’t want to add MaxTrax to the outside of my vehicle because they are too easy to rip off, and seem like they have limited utility. For me, the shovel plus conservative decisions on where to go are my best bet. This logic is why I also don’t plan to add rock sliders to my rig. 100lbs of weight for something you could completely avoid using by calling it before you find yourself in a sticky situation seems silly to me.

Compressor - self-explanatory - I’m switching from an ARB Dual to an ARB Single (swapping with a friend), since I have zero intention of going to a wheel size that requires that much air.

That’s all for today. I have the rest of the truck mapped out and I’m excited to keep writing. I wish I had more pictures, but the truck is in the shop this weekend.

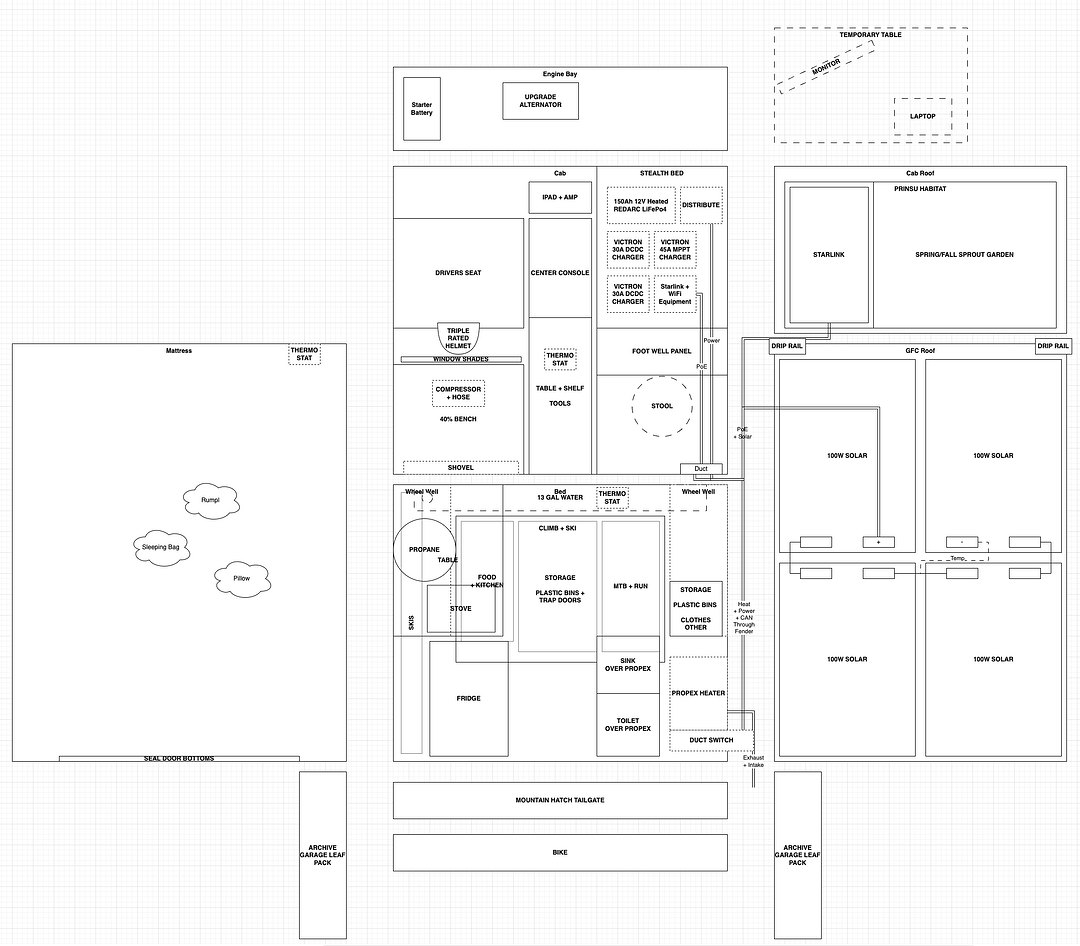

Here’s a teaser of the whole system mapped out (latest in the link, snapshotted below)